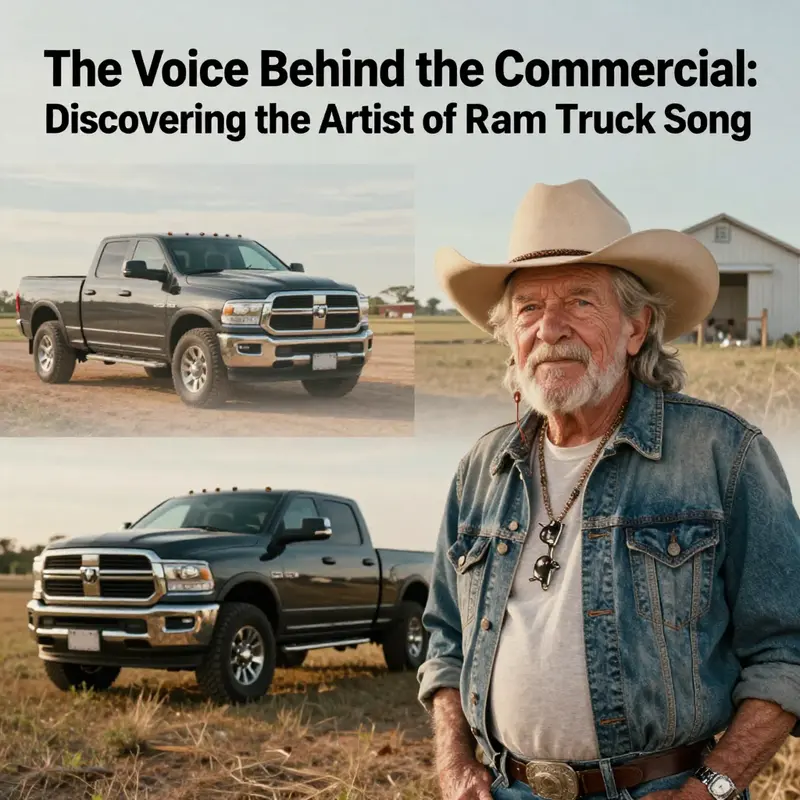

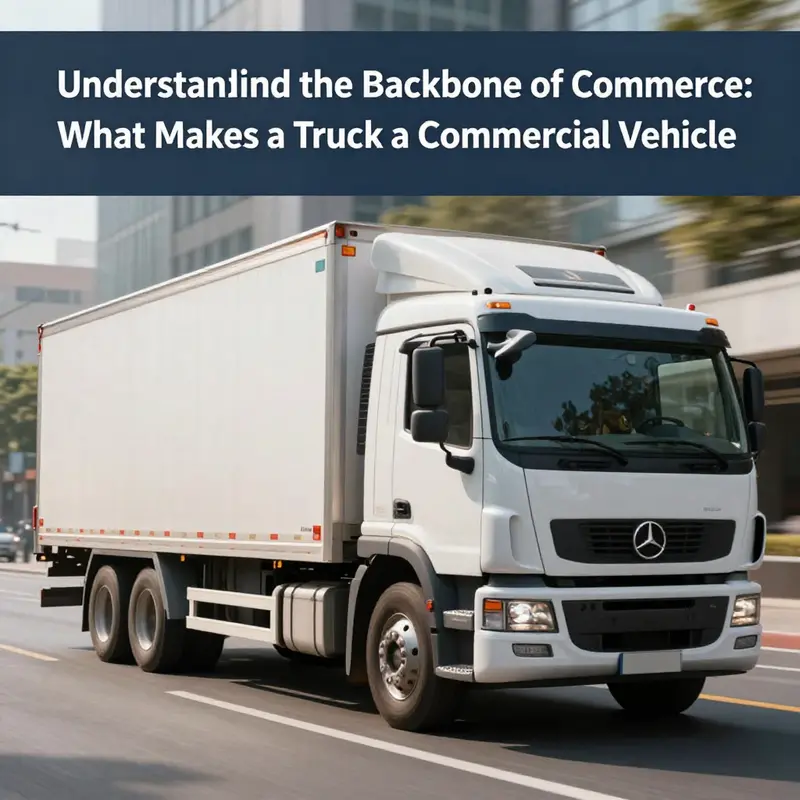

The role of trucks in facilitating commerce and ensuring operational efficiency cannot be overstated. As key vehicles for transporting goods and services, understanding what categorizes a truck as a commercial vehicle holds significant implications for trucking company owners, fleet managers, and procurement teams. This article delves into the critical aspects which define a truck’s commercial capacity, structured into three distinct yet interconnected chapters. The first chapter focuses on intended use and the various business functions that necessitate a truck’s classification as commercial. Subsequently, we explore the design and technical features engineered for heavy-duty performance and reliability. Lastly, we will review the classifications, regulatory definitions, and the implications these have on procurement and compliance. Together, these chapters establish a comprehensive framework for identifying and selecting commercial vehicles that meet business needs and regulatory standards.

From Purpose to Pavement: How Intent, Design, and Regulation Define a Commercial Truck

A truck does not earn the label commercial by accident or by appearance alone. It earns it through a precise alignment of purpose, design, and regulatory context that together frame how the vehicle is used, what it can do, and under what rules it operates. In this sense, a commercial truck is less a single object and more a functioning system purpose-built to move goods, provide services, or support business operations. The distinction becomes visible the moment we ask not just what a truck is, but what it is for, and who relies on it to do their work day after day.

The first pillar is intended use. A truck is designed and deployed to move products, equipment, or people for profit or business purposes. Its core mission centers on revenue generation or the facilitation of business processes. Freight delivery, construction material transport, waste collection, and logistics coordination each rely on vehicles that carry heavy loads, endure long hours, and operate in varied environments. Buses and shuttle services, while aligned with public transportation, also fall within this category when their operations are tied to a business model—paid rides, contract services, or municipal fleets. Ambulances, fire apparatus, and other emergency vehicles further illustrate the boundary case: they are specialized commercial assets serving critical functions that are essential to public safety and service delivery, not personal mobility. When a vehicle is routinely used to carry goods, transport personnel, or provide a service for compensation, its designation as a commercial vehicle becomes the natural consequence of its job description.

If you peel back the layers, the distinction rests on routine behavior and economic purpose as much as on the vehicle’s chassis or badge. A pickup that a tradesperson uses to haul tools between job sites still operates under a commercial model because its primary activity is business-related transportation. Conversely, a family runabout, even if it occasionally carries groceries or carpentry supplies, is not a commercial vehicle unless the scale and regularity of those tasks reframe its use as a business operation. This functional criterion matters for decision makers who plan fleets, negotiate insurance, and ensure compliance with safety and emissions standards. The business case for a vehicle emerges when the costs, risks, and returns are evaluated through the lens of work performed rather than personal convenience.

This functional frame has real consequences for design. Commercial trucks are engineered for durability and efficiency in demanding conditions. They must tolerate high-mileage workloads, frequent loading and unloading, and extended operating hours with minimal downtime. Engines are chosen for torque and reliability, drivetrains are sized to handle heavy payloads, and chassis configurations are optimized for stability under load. The goal is not merely to move a person from point A to point B, but to move product, material, or personnel in a manner that sustains production lines, service levels, and revenue streams. The result is a vehicle that emphasizes robustness over sleekness, cargo integration over mere comfort, and system interoperability over standalone performance.

A key aspect of this robustness is payload capacity and cargo space. Commercial trucks are categorized by size and payload, not by how they look. The general framework divides trucks into light-, medium-, and heavy-duty classes, a spectrum defined primarily by gross vehicle weight rating (GVWR) and the associated payload capabilities. Across this spectrum, the design choices revolve around maximizing usable space and ensuring secure, efficient loading. That often means specialized cargo configurations: van bodies optimized for quick access and staged loading; flatbeds that accommodate long items like pipe or lumber; box bodies with temperature-controlled options for perishables; and chassis with mount points for containers or lift equipment. The modularity of these configurations is not an afterthought but a central design principle, enabling fleets to tailor vehicles to the precise needs of a given operation and to retrofit them as those needs evolve.

Technology underpins this efficiency in the form of safety systems and fleet-management tools. Modern commercial vehicles increasingly incorporate telematics, GPS navigation, driver performance monitoring, and maintenance scheduling. These tools convert a single asset into part of a larger system that can be tracked, optimized, and funded as a service. Telematics enable proactive maintenance, fuel management, route optimization, and compliance reporting. For a fleet, the value of investing in safety and connectivity compounds over time: fewer breakdowns, more predictable delivery windows, and clearer insights into driver behavior and asset utilization. In practical terms, a truck becomes more than a mechanical platform; it becomes a node in a digital network that supports cost control, regulatory compliance, and customer service.

But the business function and the technical design do not operate in isolation. The regulatory frame surrounds and shapes how trucks are defined and used. In most jurisdictions, a commercial vehicle is identified not just by its physical attributes but by the purpose for which it is used. A vehicle employed to transport goods or people for hire or business purposes is subject to specific rules covering safety inspections, driver qualifications, hours of service, emissions standards, and registration regimes. This regulatory backdrop is critical for planning, because it aligns incentives around safety, reliability, and fair competition. It also ties into insurance and financing decisions, as lenders and insurers assess risk differently for commercial assets than for private passenger vehicles.

The line between personal and professional use can blur, which is why the boundary matters. A private pickup, parked in a driveway at night, may seem non-commercial. Yet if the same pickup is regularly loaded with tools, used to move a contractor between jobs, or employed to haul materials for a business on a recurring basis, it crosses into the commercial realm. The moment a business logic—revenue, service, contract fulfillment—becomes the driver of the vehicle’s utilization, its classification becomes a practical matter, not just a label. This is why many fleets emphasize not only the vehicle’s payload and performance but also the expected life-cycle costs, regulatory obligations, and the ability to integrate the asset into a larger, compliant operation.

The scope of commercial vehicles continues to broaden as markets evolve. A growing emphasis on fleet modernization and sustainability prompts investments in modular, configurable platforms that can be repurposed across different tasks. A single chassis may support a refrigerated unit for perishable goods in one season and a flatbed for construction materials in the next, enabling operators to respond quickly to changing demand without purchasing a new vehicle. This adaptability underscores how the concept of a commercial vehicle extends beyond a particular model or even a single configuration. It is the vehicle’s function in the chain of commerce—the way it moves value—that ultimately defines it as a commercial asset.

In this light, the topic becomes less about genre labels and more about how business infrastructure is built and sustained. A commercial truck is part tool, part workhorse, and part data processor. It must withstand the physical rigors of the road while delivering predictable outcomes for a supply chain, a construction project, a waste-management route, or a public-service obligation. The interplay between design and operation ensures that each vehicle contributes to reliability, safety, and efficiency at scale. This perspective helps explain why standards and specifications matter. They codify expectations for vehicles that serve commerce and provide a framework for manufacturers, fleets, and regulators to synchronize on performance, accountability, and progress.

Technology and policy increasingly intersect in this space. Electrification, advanced driver-assistance systems, and connected vehicle concepts promise to reshape how commercial fleets operate. Fleets can reduce emissions, lower operating costs, and improve workplace safety by adopting powertrains that suit high-usage demands and by deploying systems that optimize routes, monitor load security, and predict maintenance before a breakdown occurs. These trends do not merely affect the mechanics of a truck; they influence the business model that depends on it. For instance, as electric trucks mature, questions about charging infrastructure, payload impact, and total cost of ownership become central to fleet strategy. The Canadian market, in particular, is observing a rapid shift as operators weigh the benefits and challenges of electrified commercial transportation. See how electric trucks are revolutionizing the Canadian market in one contemporary exploration of this change. https://mcgrathtrucks.com/electric-trucks-revolutionize-canadian-market/.

The legal and regulatory dimension remains a constant, even as technology transforms what a truck can do. High-quality, workload-specific design must align with safety and emissions rules, which themselves evolve as new propulsion systems and service models emerge. The regulatory frame drives decisions about licensing, vehicle registration, and inspection regimes that ensure operations stay within the boundaries of public safety and environmental integrity. A robust commercial fleet does not rely on one-time compliance alone; it builds ongoing discipline around driver training, periodic inspections, and routine equipment upgrades that reflect advances in technology and shifts in policy. In practice, this means that a company’s fleet plan is not static. It grows with the business, adapts to new regulations, and evolves as the market demands more capable, efficient, and resilient vehicles.

The modular, purpose-driven design of commercial trucks also explains why dealers, operators, and insurers think in terms of asset pools rather than single units. The value of a fleet lies in the predictability of its performance across many cycles: consistent loading times, dependable fuel or energy use, and steady maintenance costs. That predictability is what makes the investment in a commercial vehicle compelling. The same vehicle that ferries pallets on a delivery run can, with a different configuration, support a different business line, making the chassis itself a long-term asset rather than a single-use tool. This versatility mirrors a broader shift in the industry—from ownership models centered on individual units to usage models anchored in fleets, service contracts, and data-enabled optimization.

In sum, a truck earns its commercial designation through a durable alliance of purpose, design, and regulatory context. It is designed not merely to move people, but to move business: to carry products to market, to carry materials to a site, to carry teams and equipment between locations, and to integrate into a system that monitors performance, enforces safety, and curates efficiencies across an operation. The truck becomes a working component of commerce, a capital asset that supports time-sensitive tasks and service-level commitments. As markets shift toward greater electrification, smarter safety systems, and more agile service models, the concept of what makes a truck a commercial vehicle expands even as its core mission remains constant: to enable people and processes to work together with reliability, scale, and accountability.

For readers looking to explore the modern implications of electrification and fleet optimization, one relevant resource examines how electric trucks are transforming the Canadian market, illustrating how changes in propulsion, charging, and design influence how a vehicle performs within a commercial framework. Additionally, the broader regulatory context remains essential reading to understand how standards evolve alongside technology. For detailed standards and guidelines, see the official guidelines available from the U.S. Department of Transportation: official guidelines.

Built for Business: How Design and Engineering Define a Truck as a Commercial Vehicle

Built for Business: How Design and Engineering Define a Truck as a Commercial Vehicle

A truck becomes a commercial vehicle when its design, engineering, and role converge around economic purpose. It is not merely size or weight that matters. The defining trait is intent: a vehicle built and used to move goods, carry passengers for hire, support services, or perform specialized business tasks. That intent shapes every technical decision, from frame thickness to cab layout, and it triggers regulatory requirements and operational practices unique to commerce.

At the heart of the distinction is structure. Commercial trucks are engineered with heavy-duty frames and reinforced suspensions. Those components resist bending and fatigue from repeated high loads. Axles, wheel hubs, and chassis rails are rated for sustained stress rather than occasional strain. Designers use thicker gauge steel, strategic crossmembers, and robust welds to maintain alignment and durability. The result is a platform that preserves payload integrity and minimizes downtime. A passenger car prioritizes ride comfort and fuel efficiency. A commercial truck prioritizes capacity and longevity.

Payload capacity and towing ability are measurable expressions of that structural focus. Gross Vehicle Weight Rating, or GVWR, sets a clear boundary between classes. Light-duty trucks sit closer to passenger cars in GVWR, but medium- and heavy-duty models are specifically built around payload and towing targets. Those targets dictate spring rates, shock absorber sizing, and axle ratios. Payload optimization also drives cargo-area design: flatbeds, box bodies, refrigerated units, and platform lifts are integrated with load distribution in mind. Cargo securement points, reinforced mounting surfaces, and step-in access become engineering criteria rather than optional add-ons.

Powertrain choices reflect operational demands. Commercial trucks often use high-torque diesel engines, selected for longevity under continuous load. Diesel engines deliver strong low-end torque, which is essential for moving heavy loads from a stop and for efficient highway cruising under load. Transmissions are designed with more gear ratios and heavier duty components to manage thermal and mechanical stresses. Cooling systems are oversized, and driveline components receive protective treatments against wear. Electric powertrains are emerging in commercial sectors, but they are engineered to meet duty cycles and charging logistics needed for business operations; markets such as Canada are seeing significant uptake in purpose-built electric models for businesses that need zero-emission fleets. For deeper context on electric adoption trends, see electric trucks revolutionize Canadian market.

Cab design also reflects a commercial mindset. Unlike passenger vehicles, cab layouts are evaluated first for ergonomics and second for comfort. Visibility, control placement, and driver endurance govern the cabin architecture. Cab types such as “normal control” and “forward control” change where the engine sits relative to the driver. Normal control places the engine forward of the cabin, increasing isolation from noise and heat and allowing larger cabs. Forward control moves the cab above or close to the engine for shorter wheelbases and better maneuverability. Additional features such as integrated storage, durable seat materials, and instrument clusters tuned for fleet diagnostics support long duty cycles. These choices minimize driver fatigue and speed routine tasks like inspections and paperwork.

Safety and operational reliability are enforced through standards. Commercial trucks must comply with braking, lighting, and stability rules from national and regional authorities. Regulations cover stopping distances for loaded configurations, anti-lock braking systems, and service-brake redundancy. Structural crashworthiness is evaluated differently than for passenger cars because trucks collide while carrying heavy mass and often protect other road users. Lighting standards ensure visibility when hauling wide loads or operating during dawn and dusk hours. Stability management systems and roll mitigation become important as center-of-gravity changes when cargo is stacked or shifted.

Emissions and environmental controls also shape engineering. Many jurisdictions require commercial engines to meet strict emissions criteria. Exhaust after-treatment systems, such as selective catalytic reduction and particulate filters, are integrated into diesel platforms. These systems change packaging and maintenance regimes for fleets. Fuel economy is important, but meeting emissions standards while maintaining torque and durability is the core challenge. As governments tighten rules, manufacturers adapt vehicle architecture to balance compliance, performance, and lifecycle costs.

Telematics and fleet management systems transform trucks into data platforms. GPS tracking, engine diagnostics, and driver behavior monitoring are standard in commercial configurations. These systems provide predictive maintenance alerts, route optimization, and proof-of-delivery logging. Telematics hardware and software are engineered for rugged environments, with sealed connectors and redundant data pathways. The ability to monitor vehicle health remotely reduces downtime and extends service intervals, which is crucial for businesses that rely on predictable asset availability.

Classification by duty remains a practical anchor. Light-duty trucks may handle local deliveries and trades work, while heavy-duty trucks move freight across regions or power construction equipment. The classification affects licensing, insurance, and allowable road use. Commercial registration often brings weight-based restrictions, special plates, and periodic inspections. In many places, a pickup used purely for personal errands stays a passenger vehicle. The moment that pickup regularly carries tools, materials, or paying passengers as part of a business, regulatory labels and responsibilities follow.

Regulatory definitions codify what design and use already imply. Authorities typically define commercial vehicles as those used to transport goods or people for business. That definition triggers obligations: different maintenance schedules, mandatory inspections, and safety equipment lists. Operators may need commercial driver licenses, vehicle permits, and specific insurance policies. These rules exist because commercial operations increase exposure; a loaded vehicle behaves very differently from an empty car in braking, steering, and collision outcomes. Compliance ensures that engineering standards meet actual on-road demands.

Maintenance practices differ for commercial trucks. Heavy-duty components demand specialized servicing intervals. Brake linings, driveline joints, and suspension bushings wear faster under load and require frequent checks. Cooling systems must be monitored to avoid heat soak during heavy operation. Preventive maintenance and condition-based replacement extend component life and reduce expensive failures on the road. Fleets often maintain dedicated shops and training programs to manage this regime efficiently.

Design choices also reflect the diversity of commercial tasks. A municipal refuse truck integrates hydraulic systems for lifting and compacting, while an emergency vehicle incorporates redundant power supplies and specialized communications. Chassis and body designers collaborate early to ensure systems do not compromise structural integrity. Load centers, where cargo weight concentrates, inform frame reinforcement and suspension tuning. Even accessories like PTO units, auxiliary generators, and crane mounts become part of the vehicle’s engineering DNA when used for business.

Economic considerations shape the engineering trade-offs. Total cost of ownership is the guiding metric for commercial buyers. Engineers balance acquisition cost, fuel consumption, maintenance needs, and resale value. Durability and serviceability can justify higher upfront cost, because downtime is often the most expensive outcome for a business. This focus explains why commercial trucks often feature modular components that technicians can replace quickly. Serviceability reduces labor costs and accelerates return-to-service times.

A final, important point is adaptability. Commercial trucks are frequently modified in the field. Bodies, liftgates, shelving, and refrigeration units are mounted after chassis delivery. Engineering provisions such as reinforced crossmembers, factory wiring harnesses, and pre-wired sensor points ease these adaptations. Manufacturers anticipate secondary equipment and include mounting rails, ballast points, and electronic interfaces. That foresight prevents ad hoc alterations that could compromise safety or durability.

Understanding why a truck is a commercial vehicle requires reading the vehicle as an engineered system aligned to business needs. Purpose-driven design, heavy-duty components, emissions and safety compliance, telematics, and maintainability all converge. When function and engineering align for commerce, the truck steps into a different category. It carries not just goods or people, but the regulatory, logistical, and economic responsibilities of a business asset.

For official guidance on commercial vehicle regulations, see the Federal Motor Carrier Safety Administration website at https://www.fmcsa.dot.gov/.

When Duty Calls: How Design, Weight, and Regulation Turn a Truck into a Commercial Vehicle

A truck becomes a commercial vehicle when its purpose, design, and regulatory context align to serve business activity rather than private use. This may sound simple, but classification rests on a mixture of objective measurements and operational facts. Regulators use clear thresholds. Operators and insurers look for signs of commerce. Manufacturers and fleet managers design trucks to meet real-world business needs. Together, these perspectives create the boundary between a privately owned pickup and a piece of equipment regulated as a commercial asset.

At the heart of classification lies intended use. A truck that routinely moves goods, carries workers, or supports a paid service is operating in commerce. That includes delivery vans, dump trucks, tow trucks, and vehicles used by tradespeople. The intent matters more than the make or model. A light pickup driven on weekends for recreation is not commercial. The same pickup, loaded with tools and used to deliver materials for a contracting business every weekday, becomes commercial because of its function. Enforcement and legal definitions look beyond appearance. They look to how a vehicle is used and how it contributes to business operations.

Design and technical features frequently signal commercial purpose. Manufacturers engineer commercial trucks for durability, payload, and continuous operation. That shows up as reinforced frames, heavy-duty suspension, and drivetrains tuned for torque over speed. Cargo areas are optimized for loading and securing freight. Vans may have shelving or bulkheads made to carry tools and parts safely. Larger trucks include specialized bodies for refuse collection, refrigerated transport, or fluid hauling. These design choices reflect business needs. They improve productivity and reduce downtime. When a vehicle carries those features as standard or as common build options, it often meets commercial criteria regardless of the owner’s intent.

Weight and gross vehicle weight rating, or GVWR, provide a measurable, regulatory anchor. GVWR is the manufacturer’s rated maximum loaded weight of the truck. Agencies use GVWR thresholds to sort vehicles into light-, medium-, and heavy-duty classes. Those classes determine driver licensing, maintenance regimes, and safety inspection requirements. In the United States, federal rules use specific marks. A vehicle with a GVWR of 10,001 pounds or more is commonly treated as a commercial motor vehicle for many regulatory purposes. Trucks designed to carry 16 or more passengers, including drivers, are also treated as commercial. Hazardous materials carriage creates another trigger. Trucks carrying materials that require placarding under federal rules fall into commercial classification regardless of weight.

Size influences everyday reality. Large tractor-trailers and semi-trucks are inherently commercial. Their scale, axle configuration, and coupling systems match long-haul freight tasks. Medium-duty chassis form the backbone of urban delivery and service fleets. Small vans and pickups sometimes sit in a gray zone. Their GVWR may keep them below certain regulatory thresholds, yet their constant use in commerce brings them under many commercial rules at the state and local level. Municipal licensing, local ordinances, and insurance contracts often treat these smaller trucks as commercial when they are used by businesses.

Regulatory definitions vary by jurisdiction but converge on common elements: use in commerce, weight or passenger thresholds, and the nature of cargo. These elements are practical. They create predictable rules for licensing, safety, and enforcement. They also align responsibilities with risk. A heavy truck that can injure other road users or damage infrastructure has higher safety obligations. A passenger-carrying vehicle used to transport people for hire must meet standards for seating, restraint, and emergency equipment. Regulatory classifications dictate which rules apply.

Those rules have direct consequences. Licensing requirements can change with classification. Drivers of heavier or passenger-oriented commercial vehicles generally need specialized endorsements or commercial driver’s licenses. Maintenance and inspection cycles often become more frequent. Fleet operators face stricter reporting requirements for hours of service and vehicle condition. Insurance premiums track risk. Commercial policies require broader liability coverage and may include cargo, hired vehicle, and fleet coverages. Tax treatment also shifts. Businesses can deduct operating expenses, depreciate vehicles, and claim specific credits, but they must comply with the rules tied to those benefits.

Beyond rules, the operational reality matters. How a truck is registered, insured, and marketed reveals its role. A vehicle titled and insured as commercial, equipped with company plates or decals, and operated in a schedule of business routes will be treated as commercial by regulators and courts. Conversely, a personal vehicle sporadically used for work may escape some commercial obligations, but that fact pattern creates risk. Occasional business use can expose an owner to liability if a claim alleges commercial operation. Clear, consistent documentation and proper registration reduce ambiguity.

Special categories complicate classification. Emergency vehicles, municipal equipment, and farm trucks may receive unique treatment. Governments often carve exceptions for public safety vehicles such as ambulances and fire trucks. Agricultural vehicles used only on farms or between fields sometimes face looser rules. At the same time, when those vehicles engage in commerce or operate on public roads for hire, they can lose their exemptions. Similarly, trucks carrying hazardous cargo face stringent federal standards regardless of their local classification. Those standards target the added danger of spills, fire, or environmental harm.

Technology now plays an increasingly visible role. Commercial fleets adopt telematics to track routes, idle time, fuel usage, and compliance. GPS and electronic logging devices supply regulators with records showing how a vehicle was used. Those systems make classification more transparent. They can also create liability when they show noncompliant behavior. Conversely, fleets that use telematics and advanced safety systems often reduce risk and insurance costs. Manufacturers integrate features such as stability control, collision mitigation, and driver-assist functions specifically for commercial models. Those safety improvements reflect regulatory pressure and business incentives to protect assets and people.

Regulatory enforcement balances fairness with practicality. Agencies strive to prevent misclassification that would allow entities to avoid safety and reporting responsibilities. Inspections target vehicles near threshold sizes and those in high-risk trades. At the same time, regulators recognize legitimate small businesses that rely on modest trucks. Policies often provide graduated requirements that reflect the real-world differences between a one-person handyman’s pickup and a multi-trailer freight carrier.

Real examples illustrate how form and function interact. A crew cab pickup equipped with a tool rack and company decals used daily to haul drywall will likely be considered commercial by regulators and insurers. A cargo van with a refrigeration unit delivering food to stores is clearly commercial due to its build and operation. A heavy tractor with a sleeper cab moving trailers across state lines is unambiguously commercial, subject to federal hours-of-service and inspection rules. The same chassis, if used only on private property for noncommercial hauling, may escape the brunt of those rules. These distinctions matter for operational planning, compliance, and risk management.

Classification also affects resale and market positioning. Trucks built and operated as commercial often show different depreciation curves than those used privately. Heavy wear, higher mileage, and customized bodies reduce resale value in some markets. Conversely, certain commercial builds, like refrigerated units or flatbeds, retain value in niche markets. Market signals influence purchasing decisions. Fleet managers choose models with the right GVWR, axle ratings, and warranties to match duty cycles. They plan maintenance with regulatory inspections in mind. Used-truck buyers scrutinize service histories and intended past uses to judge future reliability.

Ultimately, whether a truck is commercial comes down to a practical question: what is the truck doing, and how was it built to do it? That question captures both the legal tests used by regulators and the operational realities faced by businesses. Weight classes, passenger capacity, and hazardous materials rules provide objective thresholds. Design, build, and technology offer clear evidence of commercial intent. Registration, insurance, and documented routes reveal how a vehicle functions in practice. When these elements align, the classification is clear. When they diverge, stakeholders must look to records, inspections, and local rules to determine the correct status.

Understanding the intersection of design, use, and law helps operators and owners make better choices. Proper registration and insurance match legal obligations to business needs. Choosing the right chassis and body prevents overloading and reduces wear. Using telematics and routine maintenance keeps fleets compliant and safe. For anyone deciding whether to register or operate a truck as commercial, it is useful to consult authoritative sources on specific thresholds and obligations. For readers in the United States, the Federal Motor Carrier Safety Administration provides detailed guidance on weight, passenger, and hazardous materials triggers and how they apply. For regulatory details and advice, refer to the FMCSA website: https://www.fmcsa.dot.gov.

If you run a small business or manage a fleet, remember that classification affects more than compliance. It shapes insurance, finance, maintenance, and resale. It also frames the legal responsibilities you accept when carrying goods or people. A careful approach to specification, registration, and documentation reduces uncertainty. It keeps your vehicles on the right side of the law and aligned with business goals. For broader market context and insights on how economic trends affect truck usage and sales, see the article on navigating economic uncertainties from a North American perspective: navigating economic uncertainties.

Classification is not an abstract label. It is the practical outcome of how a truck is built, used, and governed. By focusing on those three pillars—design, weight and capacity, and regulatory context—owners and operators can determine when a truck must comply with commercial rules. That clarity leads to safer roads, better managed fleets, and sounder business decisions.

Final thoughts

Understanding what constitutes a commercial vehicle is imperative for businesses that rely on trucking to support their operations. From the intended use in transporting goods and services to the intricate design features that enable them to meet rigorous demands, every aspect contributes significantly to their classification. Moreover, recognizing the regulatory requirements not only aids in compliance but also informs procurement strategies for trucking fleets. As the landscape of logistics continues to evolve, staying informed on these definitions ensures effective decision-making in acquiring and operating commercial vehicles. By grasping the critical elements of what makes a truck a commercial vehicle, industry stakeholders can enhance their fleet management practices and ultimately strengthen their business performance.