The trailer manufacturing industry is currently navigating a challenging landscape defined by weak demand, significantly influenced by sluggish freight markets. Recent statistics illustrate a remarkable decline in trailer orders, with a staggering 39% drop observed from June to July alone. This downturn has prompted manufacturers to urgently reassess and adapt their strategies to cope with the new economic realities.

The far-reaching implications of low demand extend beyond production rates to impact pricing strategies and inventory management practices. In the sections that follow, we will delve deeper into these issues, analyzing the industry’s evolving dynamics and the necessary adaptations manufacturers must undertake to thrive amid continued uncertainty.

The trailer manufacturing industry is currently grappling with notable declines in order activity and production forecasts, reflecting the challenges posed by a weak freight market. Recent statistics reveal the following key data points:

- A 5% decline in overall trailer order activity.

- A sharp 39% reduction in orders from June to July.

- Production forecasts adjusted downward from 230,000 to 187,000 units due to market challenges.

These statistics highlight the ongoing struggles faced by manufacturers, indicating a stark illustration of a sharp contraction in demand among fleets. This downturn in orders is directly tied to the sluggish freight market, which has been hindered by various economic factors, including new tariffs.

Overall, these statistics underscore an urgent need for trailer manufacturers to adapt their strategies and operations in response to the evolving landscape brought on by unfavorable market conditions.

| Manufacturer | Production Strategies | Adaptation Techniques | Inventory Management Practices |

|---|---|---|---|

| Manac | Focus on quality and customization options | Investing in automation to improve efficiency | Just-in-time inventory system to reduce costs |

| Fontaine Trailer Company | Lean manufacturing principles | Diversifying product lines for various markets | Enhanced forecasting to manage stock levels |

| Trailcon Leasing | Rental and leasing strategies | Collaborating with clients for tailored solutions | Flexible inventory systems based on demand trends |

This table provides a clear comparison of how key trailer manufacturers are adapting their production and management practices in response to the challenges posed by a weak freight market. Each company employs distinct strategies to remain competitive and responsive to changing market conditions.

Adaptation Strategies for Trailer Manufacturers

In the face of weak demand, trailer manufacturers have implemented a range of adaptation strategies aimed at stabilizing their operations and preparing for future recovery. With significant reductions in trailer orders, the industry is leaning toward production adjustments, innovative maintenance strategies, and enhanced supply chain management.

Production Adjustments

Manufacturers are curtailing production rates to align with decreased demand levels. For example, Manac has reported a noteworthy reduction in production by approximately 28% in 2024. This strategic adjustment helps prevent overproduction and accumulation of unsold inventory, improving financial stability in tough market conditions. As Charles Dutil, CEO of Manac, states, “A fleet with 50 trucks will usually replace 10, 12, or 15 trailers per year. When we enter a period like the one we’re in now, carriers simply decide not to replace a single trailer.”

Maintenance Strategies

To compensate for stagnant sales, manufacturers are exploring alternative maintenance strategies that foster long-term relationships with fleets. This entails offering diversified service packages that include regular inspections and maintenance, ensuring the trailers already in use remain operational longer. By embedding sustainability into maintenance practices, manufacturers like Fontaine Trailer Company aim to maintain their customer base and reduce costs associated with new trailer production. Alan Briley, the president of Fontaine, noted that they are navigating challenges with component manufacturers, emphasizing that durability impacts customer satisfaction.

Supply Chain Adaptations

On the supply chain front, companies are enhancing relationships with suppliers to mitigate potential disruptions. Wabash National Corp. has established deeper connections and communication channels with their suppliers, leading to reduced vulnerability in their supply chain. This proactive engagement has proven beneficial as ongoing challenges with materials have stressed the sector.

Stoughton Trailers has adopted extended lead times for ordering components, reflecting the necessity of agility in procurement strategies. Additionally, implementing safety stock levels has become a common practice, ensuring that there are adequate materials available despite fluctuating market conditions. Rick Quinn, Executive VP of Steel Warehouse, points out, “Rising costs of raw materials such as steel, lumber, and aluminum are impacting our industry. Our manufacturing teams face challenges daily in every plant.”

Overall, these adaptive strategies showcase the trailer manufacturing sector’s proactive measures to navigate current challenges while positioning themselves for future opportunities as the market stabilizes.

Industry Insights from Experts

Charles Dutil, CEO of Manac, emphasizes the drastic decisions fleets make during challenging times, stating, “A fleet with 50 trucks will usually replace 10, 12, or 15 trailers per year. When we enter a period like the one we’re in now, carriers simply decide not to replace a single trailer.” This highlights the importance of flexibility in production strategies.

Alan Briley, President of Fontaine Trailer Company, discussed the challenges regarding component costs and supply chains. He mentioned, “We don’t really know what it’s going to cost at the point where we order some things,” indicating that manufacturers must navigate uncertainty with suppliers and be proactive in their sourcing strategies to stay competitive in the market.

These insights from industry leaders underscore the pressing need for trailer manufacturers to adapt their approaches in response to the ongoing market challenges.

This image showcases the various stages of trailer production within a manufacturing facility, providing visual context for the processes involved.

This infographic visually represents the different adaptation strategies employed by trailer manufacturers, focusing on production adjustments, maintenance strategies, and supply chain management.

Market Challenges for Trailer Manufacturers

The trailer manufacturing industry is currently facing significant challenges, primarily due to the impact of tariffs and stringent inspection standards. These issues not only raise production costs but also contribute to a cautious mindset among manufacturers who are striving to navigate a volatile market landscape.

The Impact of Tariffs

Recent increases in tariffs, particularly on steel and aluminum, have substantially inflated production costs for trailer manufacturers. For instance, a 50% levy on imported steel and aluminum derivatives that took effect in June 2025 has led to a rise of 15% to 30% in costs for various heavy-duty trailers. This increase burdens manufacturers like Manac and Fontaine Trailer Company, making it difficult for them to maintain competitive pricing without sacrificing margins.

The U.S. trailer manufacturing sector has reported a 43% decrease in trailer orders from June to July 2025, with the ongoing tariff situation compounding the decline in demand. Fleet operators are extending the life cycles of their equipment, hesitating to invest in new trailers amidst rising costs. As noted by industry experts, the financial implications are far-reaching: manufacturers must either absorb these costs or pass them on to customers, further dampening demand for new equipment.

Inspection Standards and Compliance

In addition to tariffs, evolving inspection standards impose further operational burdens. The complexity of compliance increases costs and requires manufacturers to invest in additional resources, including time and capital to ensure that their trailers meet the necessary regulations. The testing, certification, and inspection (TIC) process can become labor-intensive, straining the resources of companies already battling rising material costs.

These challenges contribute to a pervasive cautious mindset in the industry. Leaders like Jason Hirsch emphasize the fundamental need for flexibility in production strategies, facing both potential and unexpected increases in costs, and their ripple effects throughout the supply chain. This climate requires manufacturers to adopt more conservative financial practices and careful strategizing, as they brace for uncertain market conditions in the near future.

As the trailer manufacturing industry navigates the challenges posed by weak market conditions, strategic adaptation has become increasingly crucial. The significant declines in trailer orders and production underscore the realities manufacturers must face amidst economic uncertainties and rising material costs due to tariffs.

However, the horizon is not entirely bleak. Projections indicate that the industry could see a gradual recovery beginning in 2026, with production levels expected to rebound. With advancements in technology, including smart trailers and electric platforms, the landscape is shifting towards improved efficiency and sustainability.

Adapting to these changes is vital for manufacturers not only to survive the current downturn but to thrive in the anticipated recovery period. In this evolving market, flexibility in production strategies and innovative solutions will be essential as trailer manufacturers prepare for a resurgence in demand, ultimately allowing the sector to reposition itself for future growth and stability.

User Adoption Data Summary

In response to the weak freight markets, trailer manufacturers are adapting their strategies and technologies to meet changing user demands. Here are the key adaptations and insights:

Production Adjustments

Manufacturers have significantly reduced output to align with decreased demand. For instance, U.S. trailer production in 2024 was around 235,000 units, a 26.1% decrease from 2023. The projections for 2025 estimate production between 217,000 and 234,000 units, showing ongoing adjustments to market conditions.

Supply Chain Diversification

To mitigate the effects of increased tariffs on steel and aluminum, companies have diversified their supply chains. As an example, Hyundai Translead invested $35 million in a steel processing plant in Mexico to bypass U.S. import duties.

Technological Integration

Telematics systems are being widely adopted to enhance fleet management. The trailer telematics market is projected to grow from $0.77 billion in 2024 to $1.41 billion by 2030, driven by the need for real-time data on trailer conditions, location, and maintenance.

Product Innovation

Manufacturers are also innovating by developing trailers with lightweight materials for improved fuel efficiency. For example, Schmitz Cargobull has introduced models featuring composite panels and aerodynamic designs, offering potential fuel savings of up to 10%.

Market Forecasts

Despite the challenging conditions, the semi-trailer market is expected to grow from $38.7 billion in 2025 to $66.8 billion by 2035, at a CAGR of 5.6%. This growth is largely fueled by modernization in logistics and the expansion of e-commerce, indicating a proactive response to the current market landscape.

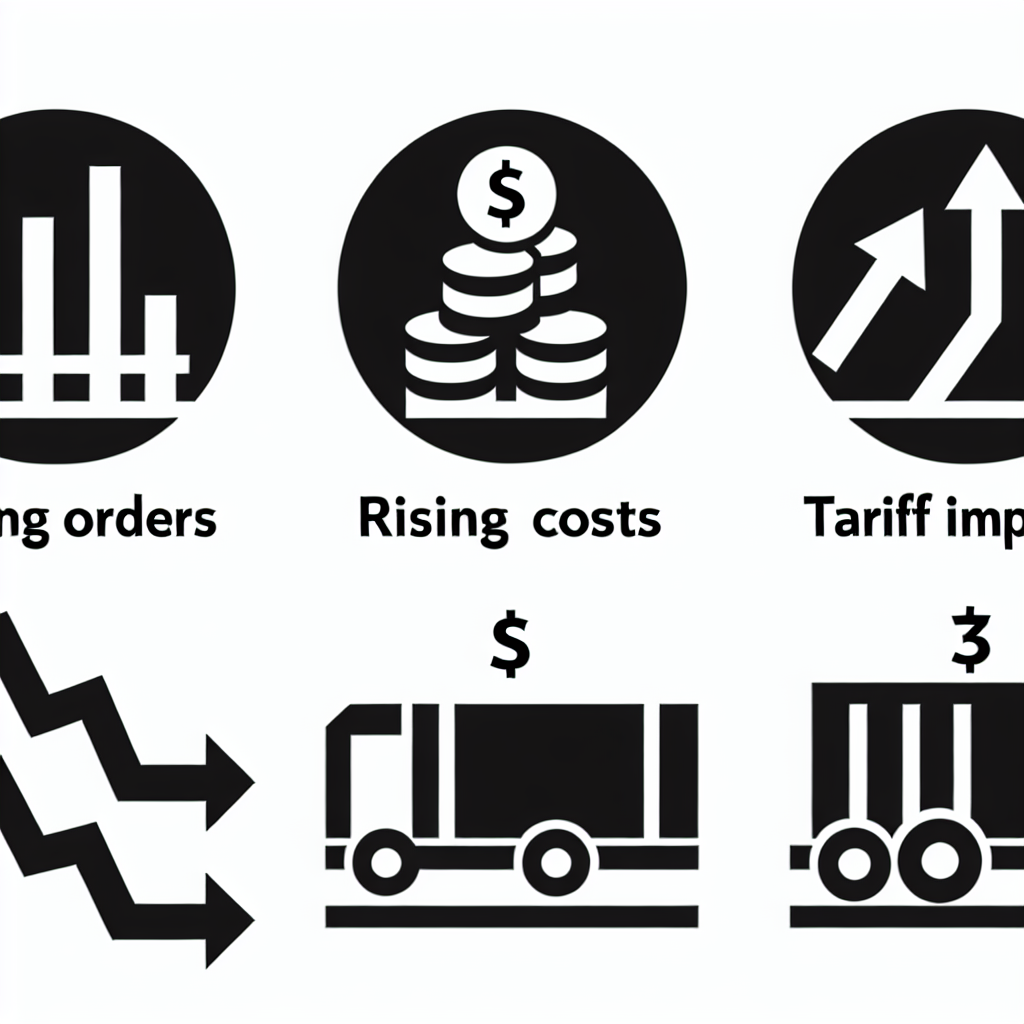

Main Challenges of the Trailer Manufacturing Sector

-

Declining Orders: The trailer manufacturing sector is experiencing a downturn with a significant decline in order activity, emphasizing the industry’s struggle to maintain steady production levels. -

Rising Costs: Increased tariffs on key materials have placed additional financial pressure on manufacturers, affecting profit margins and operational costs. -

Tariff Impacts: Ongoing trade tariffs have disrupted supply chains and raised the costs of raw materials, leading to a cautious outlook among industry players.

These visual bullet points succinctly summarize the key challenges facing the trailer manufacturing sector in the current economic climate.

Market Challenges for Trailer Manufacturers

The trailer manufacturing industry is currently facing significant challenges, primarily due to the impact of tariffs and stringent inspection standards. These issues not only raise production costs but also contribute to a cautious mindset among manufacturers who are striving to navigate a volatile market landscape, highlighting ongoing trailer manufacturing industry trends.

The Impact of Tariffs

Recent increases in tariffs, particularly on steel and aluminum, have substantially inflated production costs for trailer manufacturers. For instance, a 50% levy on imported steel and aluminum derivatives that took effect in June 2025 has led to a rise of 15% to 30% in costs for various heavy-duty trailers. This increase burdens manufacturers like Manac and Fontaine Trailer Company, making it difficult for them to maintain competitive pricing without sacrificing margins. Moreover, the U.S. trailer manufacturing sector has reported a 43% decrease in trailer orders from June to July 2025, with the ongoing tariff situation compounding the decline in demand. Fleet operators are extending the life cycles of their equipment, hesitating to invest in new trailers amidst rising costs. As noted by industry experts, the financial implications are far-reaching: manufacturers must either absorb these costs or pass them on to customers, further dampening demand for new equipment.

Inspection Standards and Compliance

In addition to tariffs, evolving inspection standards impose further operational burdens. The complexity of compliance increases costs and requires manufacturers to invest in additional resources, including time and capital to ensure that their trailers meet the necessary regulations. The testing, certification, and inspection (TIC) process can become labor-intensive, straining the resources of companies already battling rising material costs.

These challenges contribute to a pervasive cautious mindset in the industry. Leaders like Jason Hirsch emphasize the fundamental need for flexibility in production strategies, facing both potential and unexpected increases in costs, and their ripple effects throughout the supply chain management systems. This climate requires manufacturers to adopt more conservative financial practices and careful strategizing, as they brace for uncertain market conditions in the near future.

User Adoption Data Summary

In response to the weak freight markets, trailer manufacturers are adapting their strategies and technologies to meet changing user demands, reflecting crucial trailer manufacturing industry trends and effective trailer supply chain management practices. Here are the key adaptations and insights:

Production Adjustments

Manufacturers have significantly reduced output to align with decreased demand. For instance, U.S. trailer production in 2024 was around 235,000 units, a 26.1% decrease from 2023. The projections for 2025 estimate production between 217,000 and 234,000 units, showing ongoing adjustments to market conditions driven by the latest industry trends.

Supply Chain Diversification

To mitigate the effects of increased tariffs on steel and aluminum, companies have diversified their supply chains. As an example, Hyundai Translead invested $35 million in a steel processing plant in Mexico to bypass U.S. import duties. Such strategic moves help enhance overall supply chain management in trailer manufacturing.

Technological Integration

Telematics systems are being widely adopted to enhance fleet management. The trailer telematics market is projected to grow from $0.77 billion in 2024 to $1.41 billion by 2030, driven by the need for real-time data on trailer conditions, location, and maintenance. Incorporating advanced features aligns with trailer manufacturing industry trends toward automation and efficiency.

Product Innovation

Manufacturers are also innovating by developing trailers with lightweight materials for improved fuel efficiency. For example, Schmitz Cargobull has introduced models featuring composite panels and aerodynamic designs, offering potential fuel savings of up to 10%.

Market Forecasts

Despite the challenging conditions, the semi-trailer market is expected to grow from $38.7 billion in 2025 to $66.8 billion by 2035, at a CAGR of 5.6%. This growth is largely fueled by modernization in logistics and the expansion of e-commerce, indicating a proactive response to the current market landscape.

As we transition from statistical insights to a practical examination of industry responses, it is important to appreciate how the observed declines specifically inform the strategic decisions of trailer manufacturers. In light of the considerable reductions in trailer order activity and production forecasts, we can observe how manufacturers adapt their approaches to survive and thrive in this tough economic climate.

Moving forward, the following section will highlight comparisons among major manufacturers, elucidating the diverse strategies they implement in response to the pressing challenges identified previously. Through this lens, we gain deeper insights into the intricate relationship between market realities and operational adaptations.