Understanding where Isuzu commercial trucks are manufactured provides critical insights for fleet managers, procurement teams, and logistics firms. As a leader in the trucking industry, Isuzu boasts an extensive global production network designed to meet diverse market demands. This article delves into four key manufacturing locations: Japan, Thailand, India, and China. Each chapter will explore these facilities’ distinctive roles in maintaining Isuzu’s commitment to quality, performance, and efficiency, offering vital information for those invested in the commercial vehicle landscape.

From Yokohama to the World: Japan as the Heart of Isuzu Commercial Truck Manufacturing

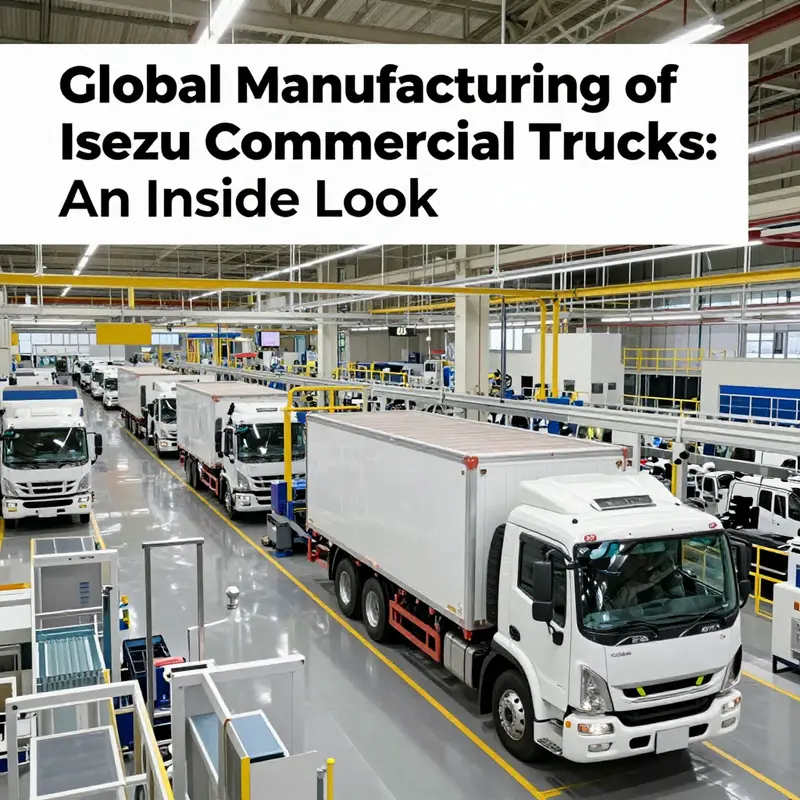

Isuzu commercial trucks sit at a crossroads of global commerce, where regional demand, regulatory nuance, and relentless engineering converge. The story begins in Japan, a country that serves not just as a production site but as the strategic nerve center from which a worldwide network of assembly plants, design studios, and testing grounds emanates. In this narrative, Japan functions as the heart and mind of Isuzu’s truck-making program, a place where precision, discipline, and a long-standing tradition of quality translate into durable vehicles that travel far beyond their birthplace. While observers might think of manufacturing in terms of a single factory floor, Isuzu’s Japanese footprint is best understood as a layered ecosystem. It includes the main production facilities in Kanagawa Prefecture, centered around Yokohama, where engineering, integration, and final assembly unfold in close concert with a rigorously controlled supply chain. These sites are more than assembly lines; they are the living laboratories where new ideas about power, efficiency, and safety are tested, refined, and prepared for broader deployment across markets that differ in climate, road conditions, and regulatory regimes.

The Yokohama region has long been a cradle for Isuzu’s commercial vehicle program. Within its industrial precincts, the company has nurtured a manufacturing culture built on meticulous quality control, standardized processes, and continuous improvement. The facilities combine lean production philosophies with a skilled workforce whose training and expertise span both conventional diesel technology and the evolving needs of modern, cleaner propulsion systems. The result is a steady cadence of components that arrive just in time, fit together with precision, and leave the line ready for the road. In this environment, engineers and assemblers collaborate across disciplines—from engine calibration and fuel system integration to chassis tuning and braking performance. The aim is not only to meet local regulations but to anticipate international standards that shape customers’ expectations for long-term reliability and low life-cycle costs.

A key facet of Japan’s role lies in the integration of research and development with manufacturing. Isuzu’s Japanese operations are deeply invested in refining emissions compliance, a critical factor as governments pursue cleaner trucking fleets and municipalities seek to reduce urban air pollution. Research teams work on fuel-efficient engines, advanced aftertreatment systems, and safety technologies that raise the bar for commercial vehicles. The laboratories adjacent to production floors often simulate real-world driving conditions, exposing powertrains to a spectrum of temperatures, loads, and terrains. This integrated approach means the same engineering choices that reduce fuel consumption—such as optimized combustion, turbocharging, and advanced engine mapping—can be validated in a controlled setting before they travel to partner plants in other regions. The focus remains squarely on durability, because for operators and fleet managers, a truck’s worth is measured by uptime as much as by miles per gallon.

Beyond hardware, Japan’s contribution extends to software and control systems that help fleets manage performance, maintenance intervals, and vehicle health. The development of digital tools for diagnostics, telematics, and predictive maintenance finds its earliest and most intensive testing grounds in Japanese facilities. The result is a suite of technologies that can be scaled and adapted for markets with different service networks and regulatory requirements. When a design passes the tests conducted within these Kanagawa-based operations, it gains a credibility that resonates with customers who depend on predictable service, robust parts availability, and consistent performance across the vehicle’s life. In other words, the Yokohama hub is where a truck’s “built-in reliability” is engineered and proven before it travels to regional assembly lines and distribution centers around the world.

Yet Isuzu’s manufacturing story in Japan is not isolated from the global market. The company maintains a deliberate geographic strategy that aligns with regional demand and logistical realities. Production in Japan serves as a central hub for high-performance, durable diesel platforms and for components that require exacting tolerances and long-term quality assurance. At the same time, the broader Isuzu network embraces facilities in Southeast Asia, South Asia, and East Asia to tailor offerings for local conditions and regulatory landscapes. In Southeast Asia, for instance, plants in neighboring countries handle volumes and configurations that meet the needs of a vibrant, rapidly developing regional market. The emphasis there often centers on versatility, ease of maintenance, and legibility of service across a widely dispersed dealer network. In South Asia, manufacturing adapts to local supply chains, with vehicles configured to address road quality, climate, and the cost pressures that fleets in emerging economies navigate daily.

This distributed approach helps explain how a single corporate identity can span oceans while keeping a unified standard of engineering excellence. The Japanese hub provides core competencies—engineered performance, rigorous testing protocols, and a forward-looking stance on emissions and safety—that travel with the vehicles and infuse the entire manufacturing system with a shared DNA. The regional plants, in turn, translate these competencies into forms that respond to local realities. The result is a portfolio that can feel consistent to customers who encounter the brand in different countries, yet remains adaptable enough to be relevant to a diverse spectrum of fleets—from urban delivery duties to long-haul operations in varied climates. The effectiveness of this model rests on the ability to balance centralization and localization: central governance of design and quality, paired with local execution that respects regulatory differences, labor markets, and the specific demands of local customers.

To understand the full scope of Isuzu’s global production, it helps to step back from the plants and consider how this network interfaces with supply chains, service ecosystems, and the regulatory environments that govern commercial trucking. Japan’s leadership in engineering and quality control reverberates through the network, guiding suppliers toward the same standards of durability and efficiency that customers expect when they put a truck on the road. The domestic market, with its stringent emissions rules and safety expectations, acts as a proving ground where new materials, coatings, and control software can be refined before they are deployed elsewhere. This continuous loop—from Japan to the world and back again—ensures that the company’s trucks not only meet the letter of the law in disparate jurisdictions but also deliver a consistent owner experience in terms of maintenance intervals, spare parts availability, and predictable lifecycle costs.

From the perspective of fleet operators and dealers, the Japanese core fortifies a sense of reliability that underpins the brand’s global reputation. When trucks are designed and tested with a discipline rooted in a country’s industrial heritage, operators gain confidence that the vehicles will perform across long service lives and under demanding duty cycles. This confidence translates into lower risk when new fleets are added, lower downtime due to unexpected repairs, and more stable total cost of ownership. The connection to the broader Isuzu network is thus not merely about where the trucks are built; it is about how the company’s standards travel with the machines, how quickly service ecosystems can respond to issues, and how the fleet owner can plan with a degree of certainty that comes from a well-integrated manufacturing story.

The Isuzu model of multi-regional production reinforces a practical truth about modern commercial trucking: localization does not mean compromise on global standards. It means translating a common engineering language into configurations that respect local roads, climate, and user needs. In Japan, the emphasis remains on refining the fundamental building blocks—engine performance, fuel efficiency, emissions compliance, and safety integration—while in other regions, those blocks are assembled into packages optimized for local networks and operating conditions. This strategy pays dividends in performance and in resilience. When a region experiences supply-chain disruptions, the company’s global footprint allows it to pivot. If one plant must slow or halt production, others can compensate, keeping fleets supplied and customers satisfied. The mechanical core remains intact, while the surrounding constraints adapt to reality.

As this chapter looks at the question of where Isuzu commercial trucks are made, the answer emerges as a layered geography rather than a single line on a map. Japan anchors the operation with design certainty, engineering rigor, and a testing culture that elevates the entire brand. The regional plants carry that culture outward, tailoring it to the landscapes they serve. And through this interconnected system, Isuzu maintains a consistent promise: trucks that endure the burdens of daily work, deliver reliability in a wide range of markets, and continue to evolve in step with the industry’s push toward cleaner propulsion and smarter fleet management. For readers who want to explore the broader context of how such a global manufacturing footprint takes shape in practice, practical industry writing and case studies across the sector offer illuminating comparisons and insights. See mcgrathtrucks.com/blog/ for discussions that illuminate how manufacturers translate global footprints into regional availability and service.

For those seeking official particulars about Isuzu’s corporate structure, manufacturing philosophy, and current production footprints, the company provides detailed information through its official channels. A thorough overview of the organization, its engineering priorities, and its approach to meeting emissions and safety standards can be found on the Isuzu Motors website. These resources help connect the everyday experience of driving or maintaining a fleet with the rigorous engineering and cross-border collaboration that keep Isuzu trucks performing year after year. As markets continue to evolve, the Japan hub will likely remain central to sustaining high standards while the regional facilities adapt to new regulations, new fuels, and new customer expectations. This is how a traditional manufacturing base can stay relevant—by looping back ideas from the road into the design room and sending refined capabilities back out into production, where they become durable workhorses for customers around the globe.

External reference: Isuzu’s official site provides current details on their global operations, product philosophies, and regulatory responses. See Isuzu Motors official site for authoritative information on the company’s manufacturing approach and regional activities: https://www.isuzu.com/en/.

Thailand as the Southeast Asian Forge: How a Regional Hub Shapes Isuzu’s Global Truck Network

Thailand sits at the center of a deliberate, globally scaled plan to keep Isuzu’s commercial trucks reliable, accessible, and tailored to a wide range of road conditions. In the broader question of where Isuzu trucks are made, the answer is a map of manufacturing footprints, each location chosen for its ability to serve distinct markets while maintaining a shared standard of durability and efficiency. Thailand is not the entire answer, but it is the regional cornerstone that makes the company’s international production system coherent and responsive. The country’s geographic advantages, its well-developed industrial ecosystem, and the skilled workforce it nurtures converge to create a production line that feeds Southeast Asia and beyond with trucks designed for tough, real-world use. Yet the story of Isuzu’s Thai facilities cannot be read in isolation. It sits alongside the company’s operations in Japan, India, and China, a network that together supports markets with different climates, regulations, and growth rates. What makes the Thai chapter particularly compelling is how it blends local capability with global engineering, turning a regional plant into a proving ground for vehicles intended for emerging economies and established markets alike. It is here that Isuzu has invested significant resources to ensure that trucks rolling off the line are not only robust and economical but also adaptable to shifting customer needs as economies evolve and roads improve or expand.

The Thai footprint reflects a deliberate strategy to couple proximity to growing markets with the ability to export efficiently. Southeast Asia remains a dynamic arena for commercial transport, where freight tasks range from dense urban deliveries to long-haul operations across limited road networks and varying fuel costs. Thailand’s location offers proximity to fast-growing neighbors while providing essential port access and logistics infrastructure to reach regional markets in a timely fashion. The result is a production system that can react with precision to demand cycles in nearby countries and, importantly, to shifts in global supply chains. The Thai facilities act as a regional hub, not only because they produce a large volume of trucks but because they also anchor Isuzu’s capability to customize products for local realities while meeting worldwide quality standards. The balance of scale and specificity matters: high-volume manufacturing paired with design insight targeted at emerging market conditions creates vehicles that perform reliably where costs are a constant consideration and service networks must be resilient.

A pivotal moment in Isuzu’s Thai strategy came in 2014, when the company announced a substantial investment aimed at expanding both capacity and the means to innovate locally. The plan called for roughly JPY 100 billion to be directed toward plant and equipment upgrades, with an additional JPY 25 billion earmarked for growth initiatives that would expand the plant’s reach and capability. This was more than a capital injection; it signaled a long-term commitment to Thailand as a research and development nexus focused on trucks destined for markets that demand a careful balance of rugged performance and cost efficiency. The scale of this investment reflected an understanding that the region’s road profiles, regulatory environments, and maintenance ecosystems require vehicles engineered with an eye toward durability, ease of maintenance, and long service life. In a note that underlines the strategic thinking behind the move, Isuzu also announced the establishment of a dedicated R&D center in Thailand. This center was tasked with developing trucks tailored to emerging economies—an explicit recognition that the economics of operation in developing contexts shape product design as surely as fuel efficiency and payload capacity do.

The 2014 investment also speaks to a broader philosophy that ties local production to global standards. It is not enough to manufacture in large quantities; the products must reflect a harmony between country-specific requirements and Isuzu’s overarching engineering philosophy. The Thai plant became a place where knowledge from Japan and other centers could be adapted to the realities of Southeast Asia, including cost pressures, labor skills, and the availability of downstream service and parts networks. Local innovation, therefore, is not a concession to regionalism but a strategic lever that helps Isuzu deliver trucks that survive the rigors of frequent urban routes, dusty rural roads, and the sometimes challenging climates that define the developing world. The ripple effects extend beyond the factory floor. An integrated approach to R&D and manufacturing elevates Thailand’s role in Isuzu’s global supply chain, allowing for faster iterations on design and more rapid introductions of improvements across adjacent markets.

The Thai program’s link to global standards is reinforced by the involvement of cross-regional collaborations that influence how trucks are built and what they can do. Not long after the Thai investment strategy began to bear fruit, Isuzu’s collaboration with General Motors on next-generation pickup development highlighted how cross-company partnerships can shape production roadmaps. Although the details of the collaboration are nuanced, the effect in Isuzu’s Asia network was clear: light commercial vehicles intended for multiple markets could be harmonized to share a core engineering platform while retaining the flexibility to meet local requirements. This is where the Thai facility gains even more significance. If a regional mass production hub can also contribute to a global platform, then the trucks that roll out of the plant may be designed with a broader spectrum of uses in mind. The prospect of LCVs designed for both Indian and Thai markets, with production anticipated in 2016, illustrates a concrete step in that direction. The practical outcome is a supply chain that can pivot more quickly to changing demand patterns and regulatory landscapes, all the while preserving reliability and performance across the range of operations.

Isuzu’s Thai facilities have also helped to reinforce the company’s international export capabilities. Thailand, as the primary export base for Southeast Asia and beyond, sits within a broader, well-developed automotive ecosystem. The country’s manufacturers, suppliers, and logistical partners form a dense network that supports mass production and efficient distribution. Governmental support for industrial growth, a mature supplier base, and the country’s own manufacturing culture all contribute to smoother handoffs from factory floor to regional highway. This environment is crucial for maintaining the kind of cost efficiency and product consistency that customers demand. In a market where total cost of ownership is frequently the deciding factor for buyers—especially in emerging economies—the Thai operation helps ensure that the products are not only affordable upfront but also economical to operate and easy to service over many years of use. The result is a pipeline of trucks that can stand up to the tough realities of regional operations while still meeting the strict quality expectations that Isuzu has built its reputation on globally.

To understand the Thai site’s significance, it helps to place it within the broader Isuzu network. In Japan, the company retains its core manufacturing strength, particularly for high-performance diesel trucks that demand advanced engineering and precision manufacturing. The Japanese plants act as the technology benchmark, elevating the entire family of vehicles through continuous refinement and innovation. In China, joint ventures such as those with Daimai Isuzu produce trucks engineered for a market with distinctive regulatory environments and a rapidly evolving freight landscape, while still enabling export to other Asian markets. In India, a significant facility in Chennai serves South Asian markets with products calibrated to local conditions, customer needs, and price points. The Thai operation thus sits among a quartet of regional hubs, each aligned with the same core objective: deliver durable, fuel-efficient, and reliable trucks that can perform across diverse road types and operating contexts. The Thai plant’s advantage is to be close to the customers and the markets that drive regional demand, while its cost structure and scale ensure that it remains an efficient node within the global supply chain.

Beyond the numbers and the supply chain logic, the Thai chapter is about aligning product with purpose. Local innovations—whether in fuel systems that optimize for varying fuel prices, drivelines designed to tolerate rough roads, or cabin configurations tuned to the preferences of Southeast Asian operators—get prototyped and refined in a setting where feedback from fleets and service networks is immediate and actionable. The capacity to rapidly adapt, without sacrificing the core quality standards that define the brand, is what makes Thailand more than a production site. It is a strategic bridge that connects regional needs with global competence. This is not merely about increasing output; it is about shaping a product philosophy that respects operational realities while remaining compatible with global engineering practices. When emerging markets demand more value from every kilometer, this blend of local adaptation and global coherence becomes a competitive differentiator.

The implications of this approach extend to workforce development as well. A robust manufacturing footprint depends on a skilled labor pool, reliable training programs, and a culture of continuous improvement. The Thai facilities, supported by the investment and the R&D initiative, are designed to cultivate capabilities that transfer to downstream activities, such as after-sales support, maintenance networks, and parts distribution. A plant that can generate not only trucks but also know-how has a multiplier effect on regional mobility. It nurtures a service ecosystem, strengthens local suppliers, and reinforces the stability of the entire value chain. For fleets operating in time-sensitive markets with limited downtime, the assurance that a Thai-built truck can be serviced efficiently—thanks to familiar components, standardized maintenance practices, and regional parts availability—adds a practical and economic value that is hard to quantify in the abstract. In this sense, the Thai manufacturing strategy is a holistic one: it considers purchase price, operating costs, maintenance logistics, and the longer arc of fleet performance.

One can also view the Thai chapter through the lens of global market dynamics. The export-oriented orientation of the Thai plants means that the line between regional and global markets is not fixed; it shifts with trade winds, currency movements, and shifting demand patterns. Isuzu’s commitment to Thailand as a growth engine for Southeast Asia signals a readiness to absorb demand shocks in one region while supplying others that require steady output. In practice, this translates into a more resilient supply chain, where production can scale up or down with relative agility. The regionally oriented yet globally informed approach helps the company weather economic cycles and regulatory changes, ensuring that trucks continue to meet the demands of operators who rely on trucks to keep goods moving and economies thriving.

For readers of the broader article who are tracing where Isuzu commercial trucks are made, the Thai chapter illustrates a crucial point: location matters, not merely as a geographic fact but as a strategic instrument. Thailand’s combination of infrastructure, skilled labor, supportive policy environments, and proximity to growing markets creates a powerful platform for delivering trucks that balance performance, durability, and cost. It also embodies a philosophy of manufacturing that blends regional expertise with global standards—an approach that positions Isuzu to respond to evolving freight landscapes across Asia, Africa, and beyond. While the world map of Isuzu production includes multiple sites, the Thai facilities anchor a regional capability that translates into competitive advantage; a capability that recognizes the realities of emerging economies without compromising the quality that customers around the world expect from the brand. The chapter also echoes a broader truth about modern manufacturing: the global truck network is most effective when each node speaks a language that resonates with its local markets while remaining fluent in the shared grammar of reliability, efficiency, and resilience.

In the end, the question of where Isuzu trucks are made returns to a synthesis of geography, strategy, and engineering. Thailand exemplifies how a regional hub can be more than a factory floor; it can be a living part of a global system, a place where ideas mature into vehicles that carry fleets across continents. The plant’s evolution—its investments, its R&D focus, its alignment with global partnerships, and its ability to serve as a gateway to emerging markets—embodies a practical model for how a company can stay true to its engineering ethos while staying agile enough to meet shifting market realities. As readers move from this chapter to the next, the conversation can continue to unfold across Japan, India, and China, where different conditions demand different configurations, yet the same core commitment remains: to build trucks that endure, adapt, and move people and goods with dependable efficiency.

External resource: Isuzu press release 2014 provides context on the scale and intent behind the Thai investment and the broader strategic implications for Isuzu’s regional and global manufacturing footprint. For additional industry perspectives on how regional production hubs influence fleet dynamics and market supply, see the broader trends discussed in industry analyses. Across the network, a single truth endures: proximity matters, but capability matters more. Thailand’s role in that equation is a testament to how a well-placed plant can help a global brand deliver durable, cost-effective trucks to fleets that keep economies moving.

Made in India, Shaped for India: Isuzu’s Localized Truck Manufacturing Within a Global Footprint

The question of where Isuzu commercial trucks are made opens a story about a company that threads a global manufacturing network into the needs of local markets. Isuzu operates across several strategic plants, with a footprint that spans Japan, Thailand, India, and China. Each site anchors a distinct position in the company’s broader supply chain, yet every factory exists to deliver reliable, durable, and fuel-efficient trucks to customers who confront very different road conditions, regulatory environments, and maintenance ecosystems. In the Indian context, this positioning is especially telling. The country is not just another manufacturing location; it is a focal point where localization becomes a strategic advantage. By understanding India’s production story, readers gain insight into how Isuzu connects regional demand with global engineering expertise, and how the resulting vehicles are designed to thrive in both rural lanes and congested urban corridors.

Japan remains Isuzu’s technical heart. It is where rigorous engineering, advanced diesel technology, and the most demanding quality standards converge to set the benchmark for the brand. The products that emerge from Japan carry a reputation for robust performance and long life, particularly under heavy-use conditions that require high reliability and predictable maintenance. This technical sophistication then informs the company’s other plants, ensuring that the global lineup benefits from a shared core of engineering excellence even as local adaptations take root elsewhere. Thailand serves as a major production hub for Southeast Asia and adjacent markets, where logistics chains benefit from proximity to growing regional demand and from established supplier ecosystems. The Thailand facility helps balance production capacity with regional needs, enabling more timely deliveries and competitive pricing in a market where fleet operators value uptime and total cost of ownership.

India’s dedicated plant for light commercial vehicles and pickup trucks marks a deliberate shift from import-reliant sourcing to a locally anchored manufacturing model. The 2014 announcement of a new facility signaled a long-term commitment to localization, a response to India’s rapidly expanding commercial vehicle market and its diverse operating environments. Production began in the spring of 2016, following a substantial investment—JPY 100 billion—in plant and equipment designed to enable high-quality, cost-effective manufacturing on Indian soil. That investment was about more than the bricks and machines; it represented a pledge to build a local ecosystem, where parts, processes, and people align with India’s unique business rhythms and user needs. Local production reduces lead times and import duties, improves price competitiveness, and strengthens the company’s ability to tailor truck configurations for the distinct demands of Indian customers—from dense urban corridors to expansive rural routes.

The decision to manufacture in India also reflects a broader industrial strategy tied to joint development with General Motors. This collaboration aimed to create next-generation pickup trucks suited for developing economies, with a focus on durability, low maintenance, and resilience in challenging road conditions. In practice, this meant designing vehicles that minimize downtime, employ simple, service-friendly components, and perform reliably where road quality can vary dramatically. For Indian operators, that translates into trucks that deliver predictable fuel efficiency, easy servicing in regional service networks, and a level of dependability that reduces the total cost of ownership. These considerations are not abstract theoretical goals; they shape supplier selection, shop floor routines, and after-sales strategies across the local plant and its regional distribution framework.

Localization in India also underpins a broader commitment to local jobs and local supply chains. By producing vehicles within the country, Isuzu can draw on domestic vendors, technicians, and engineering talent, strengthening regional capabilities and contributing to economic activity outside its core manufacturing centers. This approach aligns with how fleet operators in India manage their operations: a localized supply chain tends to respond more quickly to regulatory shifts, currency fluctuations, or evolving emission standards. It also helps the company adapt to the realities of Indian road networks—where fuel efficiency, maintenance simplicity, and service accessibility can determine a vehicle’s return on investment. The plants’ modern equipment, coupled with a disciplined quality assurance regime, supports consistent output that meets international standards while respecting the costs and constraints of Indian production.

The practical outcome of this strategy is a product portfolio that honors Isuzu’s global reputation while being deeply attuned to local realities. In India, trucks must contend with varying terrain—from well-maintained highways to unpaved rural byways—alongside diverse load profiles and operating hours. The local plant’s design emphasis favors durability and ease of maintenance, features that help operators keep fleets on the road with minimal disruption. It also means the company can offer a more nuanced lineup—vehicles that balance payload capacity, fuel economy, and maneuverability in ways that are particularly relevant to Indian customers and South Asian markets. The result is a cohesive value proposition: vehicles built to endure in Indian conditions, backed by a manufacturing ecosystem that understands the country’s business tempo and regulatory environment.

To readers seeking deeper context on how regional strategies translate into on-the-ground realities, the integrated approach becomes clearer when one examines the flow from design to delivery. Engineering teams in Japan lay down the performance targets and durability benchmarks, while the Indian plant translates those targets into configurations that optimize for local fuel prices, road surfaces, maintenance infrastructure, and driver expectations. This cross-pollination between global engineering and local adaptation is essential because it ensures vehicles retain core strengths—reliability, efficiency, and long life—without becoming overly generic. The result is a product that feels built for India’s particular blend of urban density and rural endurance, yet benefits from the efficiency and quality controls that come from Isuzu’s global standards.

For readers who want a tangible sense of how these decisions play out in everyday practice, consider how a local plant’s supply chain mirrors the geography of its markets. Regional suppliers are integrated into manufacturing schedules that reflect seasonal demand, agricultural cycles, and new vehicle registrations. Local procurement not only drives cost savings but also reduces lead times, enabling fleets to refresh their inventories with minimum disruption. The practice of sourcing components close to the assembly line also cushions the operation against currency swings and import delays, common realities in large, rapidly evolving markets like India. Moreover, localized manufacturing fosters a closer relationship with regional service networks, which translates into faster parts availability, more responsive after-sales support, and a greater degree of trust between the manufacturer and the operators who rely on these vehicles every day.

Beyond the walls of the plant, the broader Isuzu strategy acknowledges that India is part of a connected regional market. The company’s presence there supports not only domestic demand but also export opportunities to neighboring South Asian economies and Southeast Asia, where similar buying patterns and regulatory considerations exist. This interconnectedness means the Indian plant is not simply a national facility but a node in a wider network designed to deliver timely, affordable, and dependable trucks across multiple markets. The ability to scale production to meet regional variations—while maintaining a consistent performance baseline—speaks to a business model that prizes both localization and global coordination. It is a model that respects the realities of local customers while leveraging the advantages of a multinational manufacturing footprint.

If readers wish to explore more about how such manufacturing and market integration unfold in practice, a current reference point can be found in the broader industry narrative that discusses regionalized production and market-specific design. For a general sense of how dealers and fleets discuss these strategies, the McGrath Trucks blog offers accessible insights into distribution and market dynamics. McGrath Trucks blog

As this chapter moves forward, the Indian manufacturing story serves as a lens through which to view Isuzu’s global approach: a deliberate, data-informed effort to localize where it makes sense, while preserving the international standards that define the brand. The balance between global quality and local relevance is not a single decision but a continuous process of listening to markets, refining processes, and reinforcing the supply chain so that each plant—whether in Asia’s industrial heartlands or elsewhere—contributes to a reliable, efficient, and durable fleet across the globe. In that sense, the question of where Isuzu trucks are made becomes a more nuanced inquiry about how a multinational company translates global engineering into vehicles that perform where people live and work—and how those vehicles, in turn, support communities and economies that rely on road transport every day.

External resource: https://www.isuzu.com.in/vehicles/light-commercial-vehicles/

Made in China, with Global Purpose: The Isuzu-Dongfeng Alliance and the Global Footprint of Isuzu Commercial Trucks

The story of where Isuzu commercial trucks come from is a story of a carefully arranged network that stretches across continents, built on a blend of Japanese engineering discipline and local manufacturing capabilities. While Isuzu maintains its roots in Japan as a cradle of its most advanced diesel technologies and rigorous quality controls, the company’s global footprint has grown to ensure trucks are built where they are needed. In this broader map, China stands out not merely as a large single factory floor, but as a pivotal node in a multi-national production system. Here a strategic alliance between Isuzu Motors Limited of Japan and a major Chinese automaker enables localized production that meets domestic demand and supports selective exports to neighboring regions. The result is a production model that combines the reliability and fuel efficiency associated with Isuzu engineering with the scale, supply chains, and distribution networks available in China. This arrangement exemplifies how a global truck maker can sustain price competitiveness, shorten delivery times, and adapt to local market needs without compromising the core attributes that have defined the Isuzu brand for decades.

At the heart of the China chapter is a joint venture that links Japanese know-how with Chinese manufacturing muscle. This partnership, formed to capitalize on China’s massive commercial vehicle market, blends Isuzu’s emphasis on durability and long-term value with the host partner’s deep local market insight, supplier ecosystem, and expansive dealer network. The collaboration is more than a contractual agreement; it is a long-term platform for product development, localization, and after-sales service that keeps fleets moving in a market where uptime matters as much as upfront price. The joint venture model allows the company to tailor production lines to regional demand while preserving the global standards that customers everywhere expect. It is a practical response to the realities of modern logistics: trucks must be built closer to where they are used, and the manufacturing strategies must be nimble enough to respond to shifts in volume, tariffs, and material costs.

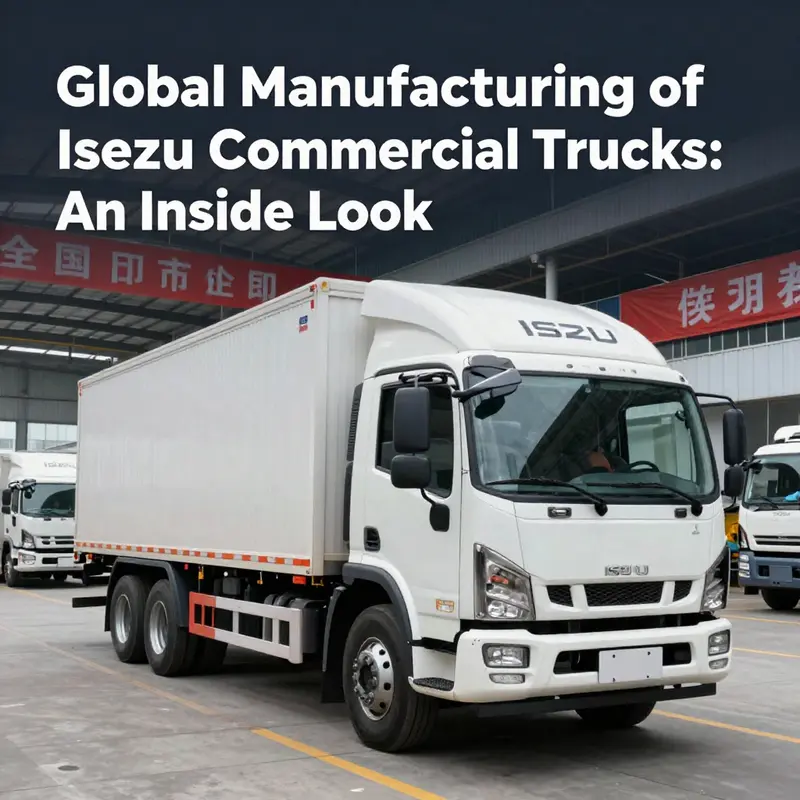

From a product perspective, the China-made lineup is organized around broad segments that cover light, medium, and heavy-duty applications. This segmentation ensures that fleets of different sizes, from last-mile operators to regional haulers and construction contractors, can source trucks with appropriate chassis configurations and engine choices. The emphasis here is not on branding alone but on matching performance attributes—durability, reliability, and fuel efficiency—to the diverse operating environments across urban cores, rural corridors, and port logistics. The joint venture leverages this alignment by combining Isuzu’s diagnostic and engine-management expertise with the host partner’s ability to engineer and assemble vehicles at scale. The result is a series of offerings that are robust for the long hauls and adaptable for the city streets, the chilled warehouse routes, and the harsh conditions of regional service.

What makes the China-based production meaningful goes beyond the assembly lines themselves. It rests on the integrated supply chain that supports a reliable cadence of production. This ecosystem benefits from regional suppliers who are accustomed to the stricter quality controls that Japanese engineering standards demand, while also enjoying the speed and cost advantages that come from proximity to customers. In a country where distribution networks can span thousands of kilometers, the ability to coordinate parts, sub-assemblies, and final assembly in a synchronized fashion reduces lead times, lowers stocking costs for dealers, and shortens the time from order to delivery. The advantage is more pronounced in markets where fleets require steady replacements and upgrades as new emission standards and regulatory expectations come online. In such contexts, a China-made truck can be both a competitive purchase and a responsible, future-ready asset for a buyer who values uptime and total cost of ownership.

The market dynamics in China reinforce why this joint venture remains central to the Isuzu global story. China’s commercial vehicle sector, while intensely competitive, rewards brands that combine proven reliability with predictable servicing costs and a broad regional support network. The Isuzu approach in this market emphasizes long-term value, not merely initial price advantages. Fleet operators who prioritize fuel efficiency, engine longevity, and ease of maintenance tend to recognize that the total cost of ownership over a truck’s life can tilt decisions in favor of brands with a track record of durable performance. In that light, the joint venture’s emphasis on durable chassis families, adaptable cab configurations, and service-friendly design gains clear appeal for customers who view their trucks as strategic investments rather than one-off purchases. The competition—dominated by other large builders with entrenched domestic production—receives a credible counterpoint from Isuzu that is anchored in the promise of reduced downtime and lower operating costs over the vehicle’s lifetime.

Beyond the broad market share and steady demand, the Isuzu-China collaboration has carved out a distinctive niche by focusing on specialized configurations. In practice, this means tailored solutions for applications that require extra uptime and rugged performance, such as heavy-duty tasks in harsh environments, and configurations designed for precise operational roles like heavy lifting, refrigerated transport, or specialized service duties. These niche capabilities help Isuzu differentiate itself in a crowded field where cost competition is intense and where customers increasingly value the ability to source not just a truck, but a truck that can be trusted to perform in mission-critical assignments. This strategic emphasis on specialized applications underpins a credible market position in both domestic sales and selective exports to neighboring markets, where buyers look for the same blend of reliability and efficiency that Isuzu is known for elsewhere, but with a localized fit and support network.

The strength of the local plant in China also rests on the region’s sophisticated logistics and its dense industrial cluster. In particular, the industrial heartland known for its concentrated manufacturing talent provides access to a robust supply chain ecosystem. The roughly cited figure of more than sixty percent of China’s specialized truck manufacturing clustering in this region illustrates how proximity to suppliers and peers supports faster development cycles, better quality control, and more predictable production rhythms. This regional advantage translates into tangible benefits for customers: shorter lead times, faster customization for fleets, and the flexibility to adjust volumes in response to demand shifts. It also matters for service and spare parts availability, which in a market with wide geographic dispersion translates into lower downtime for fleets and improved total cost of ownership. The joint venture’s footprint in this environment reflects a broader industry reality: modern commercial trucking demands not only sophisticated engines and durable frames but also a carefully orchestrated network of partners who can deliver parts, service, and technical support where and when fleets need it most.

As manufacturing in China has matured, Isuzu trucks produced under the joint venture have become a part of broader export strategies. The region has become a springboard for shipments into adjacent markets in Asia and beyond. While domestic sales remain a priority, the ability to export trucks that carry the Isuzu reliability badge helps diversify regional risk and align with global demand trends for fuel-efficient, low-maintenance fleets. This export dimension is especially valuable in regions that face similar operating challenges—rough terrain, long-haul routes with variable fuel prices, and a need for trucks that can stand up to long service lives with minimal downtime. The synergy of a strong Chinese factory, a rigorous Japanese engineering backbone, and an expansive regional distribution network therefore supports a twofold mission: meeting domestic demand with a locally manufactured option and serving as a source for reliable, capable trucks in nearby markets that benefit from proximity to Isuzu’s Chinese operation.

The value of this manufacturing arrangement becomes clearer when one considers the ongoing evolution of fleet management and ownership costs. Fleets increasingly seek predictable maintenance budgets and predictable uptime, especially for operations where every mile counts. In this environment, China-made Isuzu trucks can offer advantages in terms of parts availability, service network reach, and after-sales support across multiple provinces and neighboring markets. The joint venture’s business model is designed to be responsive to these realities. It supports a modular approach to configuration, enabling fleets to specify the cab and chassis options that meet their exact operating requirements while preserving the core attributes that define the Isuzu name—robust engines, proven transmissions, and a reputation for durability. The outcome is a product and service proposition that blends global standards with local execution to create a compelling value proposition for customers who operate in markets where reliability translates directly into productivity and profitability.

For readers who want a deeper dive into the external landscape of Chinese truck manufacturing and the kinds of listings that populate the market, an external reference provides a snapshot of how local production integrates with global supply chains. External resource: https://www.made-in-china.com/products/8704230090.html.

Within the broader discussion of how and where Isuzu commercial trucks are made, it is also useful to acknowledge the academic and industry commentary that frames the decisions behind joint ventures like the one in China. Analysts from global markets note that localization does not merely reduce logistics costs; it also enables manufacturers to tailor products for regulatory environments, emission standards, and customer usage patterns. In the case of Isuzu, the China joint venture reflects a deliberate strategy to harness local manufacturing strengths while maintaining a consistent global ethos around vehicle efficiency and reliability. The resulting vehicles are not simply imported ideas reassembled on a Chinese factory floor; they are the product of a collaborative ecosystem designed to bridge regional competencies with a shared mission of durable performance under challenging conditions. In practice, this means that the trucks produced here are part of a larger, coherent approach to global manufacturing where regional centers act as both production hubs and service outposts, keeping fleets on the road and operators on schedule. The chapter of Isuzu’s story in China, therefore, is a testament to how cross-border partnerships can yield machines that travel far beyond their point of origin while still reflecting the core values that define their brand.

To connect this discussion with ongoing industry conversations, readers can explore how market trends in used-truck sales and fleet renewal cycles influence manufacturing mix and regional production decisions. See the analysis on current trends in used-truck sales growth for a sense of how buyers’ needs shift with economic conditions and fuel prices. This is one of the ways the Isuzu-China joint venture remains responsive to a changing market while preserving the fundamentals of engineering excellence that support long ownership cycles and predictable maintenance costs.

Final thoughts

In conclusion, Isuzu’s global manufacturing strategy spans across essential locations in Japan, Thailand, India, and China, each playing a pivotal role in representing the brand’s commitment to quality and performance in commercial trucking. For fleet owners and procurement teams, understanding these manufacturing hubs offers deeper insights into the reliability and efficiency of Isuzu trucks. As companies navigate their logistics and operational strategies, selecting vehicles from a manufacturer with such a strong production pedigree ensures that they are investing in technology, durability, and performance tailored to their specific regions.