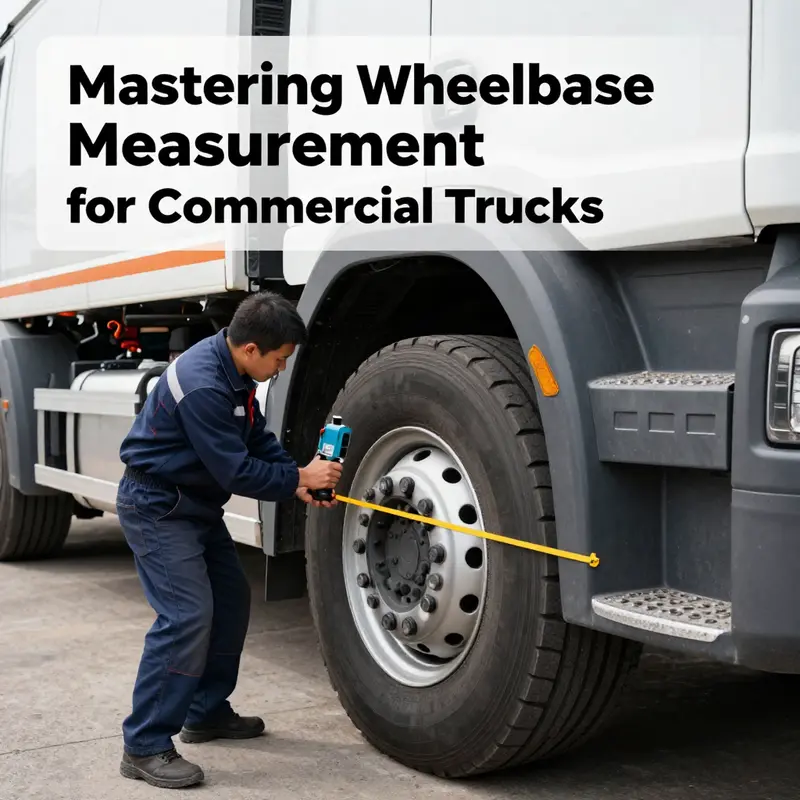

Measuring the wheelbase of a commercial truck is a vital task for trucking company owners, fleet managers, and procurement teams in construction and logistics. The wheelbase not only affects vehicle handling and stability but also impacts cargo capacity and overall performance. Therefore, understanding how to measure it accurately is critical for maintaining operational efficiency. This guide provides a comprehensive approach, covering preparation, tools, identification of axle centers, measurement techniques, and the importance of adhering to manufacturer specifications. By mastering these essential steps, professionals can ensure optimized vehicle performance and longevity, significantly contributing to their operational objectives.

From Hub to Hub: A Practical, Precision-Driven Guide to Measuring Wheelbase on a Commercial Truck

Measuring wheelbase is more than a numeric exercise; it is a precise reading of the truck’s longitudinal skeleton. The wheelbase—the distance between the center of the front steering axle and the center of the rear axle, measured along the vehicle’s length—directly informs hitch compatibility, trailer matching, stability under load, and regulatory documentation. In fleets and workshops alike, a dependable wheelbase figure translates into safer handling, more predictable maintenance planning, and fewer surprises during inspections. When you approach the task with a calm method and the right tools, the measurement becomes a straightforward affirmation of how the chassis was designed to carry its loads. This is not a trick of geometry but a test of disciplined procedure, one that respects the engineering that keeps big rigs aligned, balanced, and ready for the road.

Preparation is the quiet before the measurement storm, and it matters as much as the taping itself. Park the truck on a level, flat surface with the steering wheels pointed straight ahead. Any tilt, slope, or turn will tilt the axle centers relative to the ground and introduce errors you must chase away with more measurements. Empty the vehicle of cargo and passengers so the chassis sits in its standard state, free from unusual weight distribution. Confirm that all tires are inflated to the manufacturer’s recommended pressures; deviations can subtly alter suspension sag and even the tire’s contact with the ground, shifting the apparent wheelbase by small but consequential amounts. While it may be tempting to rush, the integrity of the measure depends on calm, deliberate preparation. The car or truck should feel unmoving, almost incapable of responding to a gentle nudge, so the geometry you read reflects design intent rather than temporary deformation.

Next come the axle centers, the critical reference points that anchor the entire measurement. Identify the center of the front axle, typically the midpoint of the front axle beam or the hub assembly. Then locate the center of the rear axle, be it the drive axle or the center of tandem axles, if present. For trucks with multiple rear axles, the wheelbase is conventionally measured to the center of the first rear axle, not the last, because that first rear axle is the key drive point that interacts most closely with the front axle during normal operation. This convention matters when you compare your field measurement to manufacturer data or to the vehicle’s service manual; it keeps every figure speaking the same language. With the centers identified, you can set up the measurement path with confidence, knowing the geometry you’re chasing is the true centerline distance rather than a peripheral approximation.

Tools choice matters as much as technique. A steel tape measure remains the workhorse for many technicians due to its reliability and the tactile feedback it provides. It must be long enough to span the entire distance and, crucially, non-stretchable to preserve accuracy over its length. A laser distance meter offers a modern alternative, especially when long spans or tight spaces make a tape difficult to manage. If you use a laser, you still need to anchor your measurement to exact center points and keep the line perpendicular to the axles’ centerlines. With either tool, the goal is to trace a straight, level line that mirrors the vehicle’s longitudinal axis, avoiding any downward tilt toward the ground that would distort the readout.

The moment of truth arrives when you extend the measuring line from front to rear, and the discipline you’ve practiced carries you through. Place one end of the tape at the exact center of the front axle. If you’re using a tape, run the blade along the vehicle’s centerline so it stays parallel to the ground and unobstructed by fuel lines, brackets, or other components. If you’re using a laser, position the emitter on the front axle center, then project the beam toward the rear axle center, ensuring the line stays straight and true along the chassis. The measurement must be parallel to the ground and perpendicular to the axle centers. A crooked setup invites parallax errors and makes the figure unreliable. Read the value with careful attention to where the measurement ends, and record it.

Because no single reading guarantees precision, repeat the measurement several times from different angles or positions. Three or more clean readings allow you to average out small inconsistencies—sag in the suspension, slight ground irregularities, or minor misalignments in how the tape sits on the axle center. The average becomes the wheelbase figure you’ll rely on for planning and documentation. If you notice unusual variance between trials, step back, recheck alignment, re-confirm the center points, and consider whether surfaces or tire states contributed to the discrepancy. This is the moment when attention to detail pays off in downstream reliability.

A robust practice also involves cross-checking your DIY result with manufacturer specifications. The wheelbase published by the manufacturer is derived from the vehicle’s engineering drawings and assembly tolerances, and it remains the baseline against which field measurements are judged. If your measured distance sits a bit off, it may reflect aftermarket alterations, tire radius changes, or the presence of a tandem configuration that shifts the effective drive geometry. In such cases, consult the vehicle’s service manual or manufacturer portal for the sanctioned figure, then document the discrepancy with notes about configuration, tires, and any modifications. The aim is not to prove one measurement is superior to another, but to understand how different conditions can influence the number you report.

Beyond the numbers, the wheelbase speaks to the interplay of chassis and trailer. A precise figure informs how a tractor will ride behind a given trailer, how it will handle highway curves, and how it will respond under load when the weight shifts toward the rear or the front. It also affects maintenance decisions, such as suspension work, ride-height adjustments, or alignment checks, because any change in wheelbase can subtly alter tracking and tire wear patterns. If you’re upgrading a fleet, retrofitting different trailer types, or validating a new compliance standard, the clarity of a well-measured wheelbase becomes a practical compass for decisions that affect safety, efficiency, and uptime.

The process described here is designed to be accessible to shop technicians, fleet managers, and drivers who want a concrete understanding of their vehicle’s geometry. It emphasizes a disciplined approach: prepare the vehicle, identify axle centers, choose a reliable measuring method, measure with care, and verify against authoritative data. When you align practice with the vehicle’s documented dimensions, you create a clear trail of accountability that supports audits, maintenance planning, and safety reviews. If the chapter raises questions about how similar measurements impact other aspects of vehicle performance, you’ll soon see how wheelbase interacts with different trailer configurations, load distributions, and stability across operating conditions, all rooted in that central measure of the truck’s longitudinal spine.

For readers seeking practical context and field-tested perspectives, a practical resource is available through the mcgrathtrucks blog, which offers accessible discussions tied to measurement and alignment in real-world settings. It helps translate the numbers you read into actionable decisions on the shop floor and in the yard. Reading such guidance reinforces best practices, reminds readers to verify against manufacturer data, and demonstrates how modest measurement differences translate into operational realities. The relationship between measurement technique and vehicle performance becomes a story you can apply across various truck configurations, from simple single-axle rigs to complex multi-axle fleets. To explore these practical perspectives, see the mcgrathtrucks blog.

In documenting your measurement, treat the wheelbase as a condition you can defend. Record the date, vehicle identification, axle configuration, tire pressures, and any notes about suspension state or aftermarket components. This record supports inspections, compliance, and future maintenance planning. If you’re cataloging a fleet, assemble a concise profile that includes wheelbase, overall length, track width, and front overhang. Those data points together form a reliable basis for planning, safety reviews, and budgeting—because the longer the road you intend to travel with confidence, the more precise your baseline must be.

External context can broaden your understanding of how wheelbase sits within vehicle dimensions and regulatory expectations. For broader context on vehicle dimensions and standards, external reference: https://www.nhtsa.gov/

From Ground to Gauge: A Practitioner’s Guide to Measuring Wheelbase on a Commercial Truck

The wheelbase of a commercial truck is more than a specification on a page; it is the spine of the vehicle’s handling, weight distribution, and compatibility with trailers, suspensions, and drivetrain components. When precision matters—whether calibrating a chassis, aligning a drive axle, or fitting a new suspension kit—the measurement must be exact and repeatable. The wheelbase is defined as the distance between the centers of the front and rear axles, measured along the vehicle’s longitudinal axis. In practice, that means finding true center points, keeping the measurement plane parallel to the ground, and controlling for weight, tire condition, and alignment. A careful approach reduces uncertainty and helps avoid misinterpretations that could ripple into operational or safety concerns over time.

Preparation sets the foundation for accuracy. Begin with a level, stable surface where the truck can sit undisturbed for the duration of the measurement. A flat pad or a well-prepared driveway slab works best, provided the surface remains level under the load of the vehicle. The truck should be unloaded, with no cargo or passengers that could distort weight distribution and subtly alter the geometry of the axles. This step is essential when you want the wheelbase value to reflect the vehicle’s standard geometry rather than a temporary state caused by a load. Before you start, ensure the parking brake is engaged and the vehicle is securely chocked to prevent any movement that could change the alignment as you measure.

Tire condition matters, too. Inflate the tires to the manufacturer’s recommended pressure. Under- or over-inflated tires deform slightly under load and can shift the apparent centers of the wheel hubs, introducing error into the measurement. If the truck has been sitting for some time, a quick check of both front and rear tires helps confirm they are in their normal state for the measurement session. With weight removed and tires inflated correctly, you’ll have a more reproducible baseline, which is crucial if the wheelbase is needed for precise alignment work, trailer hitch fitting, or the calibration of sensor systems that rely on accurate geometry.

Another element of preparation is ensuring the steering wheels are straight. If the front wheels are turned or if the steering geometry is out of alignment, the apparent distance between axle centers may deviate from the true value. Straightening the wheels and confirming that the truck is in a neutral, unloaded state helps minimize a common source of error. In some settings, technicians also verify that the vehicle is level in both longitudinal and transverse directions, using a simple spirit level or a digital inclinometer. Although the latter is not always necessary for routine measurements, it can be a prudent check when high precision is required for critical calibration tasks.

With the vehicle prepared, turn attention to the tools of the trade. The classic steel tape measure remains the workhorse for many shops: a non-stretch metal tape long enough to span the distance, typically at least five meters, reduces the risk of re-routing the tape and introduces a straightforward visual check along the axis. For larger trucks or environments where reaching the ends with a tape is awkward, a laser distance meter offers a non-contact alternative that delivers quick readings with impressive repeatability. The laser method helps limit human error associated with bending, sagging, or misaligning a tape across a long span. Some advanced facilities also employ 3D scanning or laser scanners for comprehensive geometric data, though these methods are usually reserved for specialized calibration or manufacturing processes rather than routine field measurements.

When selecting measurement points, you’ll typically measure from the center of the front axle to the center of the rear axle along the vehicle’s longitudinal axis. The center of the front axle is commonly taken as the midpoint of the axle beam or the hub assembly, while the rear axle center is identified at the midpoint of the rear axle beam or the hub assembly. In trucks with multiple rear axles, the standard practice is to measure to the center of the first rear axle. This convention aligns with how the wheelbase is used in most downstream applications, including chassis design, suspension tuning, and trailer connection geometry. In some cases, technicians define the front wheel center as the midpoint of the tire width—particularly when precise hub-based measurements are impractical—and then locate the rear wheel center at the corresponding rear tire centerline. Either approach should be clearly documented to ensure that the resulting wheelbase figure is interpreted correctly in maintenance manuals, service records, or equipment upgrades.

As soon as you have your tools and points defined, the measurement process itself should be performed with discipline. Place one end of the tape at the exact center of the front axle and extend toward the center of the rear axle, keeping the line as straight as possible and parallel to the ground. If you use a laser, aim the emitter at the center of the front axle and read the distance to the center of the rear axle. The line or beam must remain perpendicular to the centerlines of both axles; any angular deviation introduces a trigonometric error that magnifies across a long span and skews the result. It’s not unusual to repeat the measurement from a few different positions along the vehicle’s length or to rotate slightly around the vehicle’s midpoint to confirm that the reading remains consistent. In practice, three independent measurements—taken from slightly different positions—often provide a robust average that mitigates the risk of a single outlier skewing the result.

One practical consideration is the potential effect of structures or protrusions near the axles. The presence of brake components, differential housings, or wheel hubs can influence the exact center you identify, so it helps to be consistent in how you define those centers and to document any deviations you encounter. If the measurement is intended for precise tuning of a suspension system or for alignment troubleshooting, it can be worth taking a parallel set of measurements from the opposite side of the vehicle as a cross-check. The goal is not a one-off number but a repeatable, defensible value that can be traced back to a clear measurement protocol.

As with any measurement that informs heavy equipment work, there is value in corroborating your number with manufacturer specifications. The wheelbase dimension published by the vehicle maker is the definitive source of truth, reflecting the geometry designed and tested for the chassis. When possible, consult the service manual or the manufacturer’s data portal. Digital records from a dealer’s portal or the owner’s manual often include the wheelbase frame dimension, and these figures can be a reliable reference to confirm the DIY measurement. If a discrepancy arises between your measurement and the manufacturer’s specification, prioritize the official spec and recheck with careful attention to the center point definitions and alignment.

For those who want a consolidated view of practical tips and related measurements and procedures, the McGrath Trucks Blog offers a broad range of maintenance and inspection guidance that complements hands-on wheelbase work. McGrath Trucks Blog can serve as a useful companion resource for technicians seeking quick refreshers or cross-checks on vehicle geometry and service practices.

The end result of a careful process is more than a number. A well-documented wheelbase measurement becomes a reliable datum point for diagnostic work, aftermarket upgrades, and fleet maintenance planning. When wheelbase figures are used in alignment calculations, loader and drive-train configurations, or trailer compatibility assessments, the integrity of the input data directly affects outcomes. In that sense, the method you choose matters as much as the number you obtain. It is worth investing the time to remove variables—level ground, proper tire pressures, wheels straight, and stable measurement conditions—so that the wheelbase value speaks with clarity and confidence.

As you complete the measurement, record the averaged value along with the method you used: the tool (tape or laser), the centers defined (front axle center and rear axle center according to your chosen convention), and the surface and load state of the truck at the time of measurement. This record will simplify future checks, help reconcile any differences that appear in subsequent maintenance work, and support traceability in fleet management or engineering projects. If you are calibrating systems that rely on precise geometry, such as differential models or wheel encoders, consider scheduling a professional verification with alignment equipment to corroborate DIY results.

For readers seeking further external context on measurement practices and best practices for wheelbase determination, see an external reference that outlines practical methods and considerations that echo the approach described here: https://www.mechanicalland.com/2024/10/how-to-measure-wheelbase-of-a-truck.html.

Tracing the True Center: Finding Axle Centers to Anchor Accurate Wheelbase Measurements on a Commercial Truck

Wheelbase is not just a number on a spec sheet; it is the spine of a truck’s geometry, tying together handling, load distribution, and overall stability. If you want to measure it with confidence, you must first locate the axle centers—the geometric midpoints that serve as the endpoints of the wheelbase measurement along the vehicle’s length. Identifying these centers accurately is a blend of leveraging official data and applying precise field techniques. When you start from a well-documented reference point, you set up a measurement that not only reflects the truck’s true geometry but also remains defensible under inspection, maintenance planning, or resale evaluation.

The most reliable path begins with manufacturer specifications. The factory wheelbase is defined in the vehicle’s technical manuals and service documentation, and these sources often include diagrams that pinpoint the center points relative to the chassis, mounting pads, or the axle housing. If you can access the official documentation, you are aligning your measurement with the geometry that the manufacturer used to define the wheelbase in the first place. In practice, this means identifying the front axle center as the midpoint of the front axle beam or the center of the front wheel hubs, and locating the rear axle center as the midpoint of the rear axle beam or the center of the rear wheels’ hubs. For trucks with multiple rear axles, the wheelbase is typically measured to the center of the first rear axle. Before you pick up any tape, consider marking these centers on the chassis or axle housings if the documentation allows; this gives you a fixed frame of reference to cross-check against the numbers you read later.

When the official documentation is unavailable, reliable identification still remains within reach through careful observation and disciplined technique. On solid axles, look for a visible center bolt or a machined flat on the axle housing—the features that engineers often use to indicate the true center. These cues can be subtle, especially on older or painted components, so clean the surface and use adequate lighting to reveal them. On tapered axles, the center point is effectively at the intersection of the two conical surfaces as the axle narrows toward the hub. Pinpointing this visually requires experience and a trained eye, but with patience you can locate a point that consistently represents the true center.

A practical fallback that does not require specialized tools is the string method. Stretch a taut string across the axle housing, perpendicular to the axle line. If you place strings at opposite ends of the axle and bring them into alignment, their intersection on the housing often marks the axle’s center with reasonable accuracy. While not as exact as a verified center bolt or a laser-dominated measurement, this technique gives you a defensible reference point when the time and resources for high-tech equipment are not available. The string method becomes more reliable when used in conjunction with a direct visual check of the identified center points, effectively giving you a cross-check that reduces uncertainty.

In today’s professional environments, advanced measurement technology is the gold standard for axle center identification. Laser alignment systems can map the axle geometry with sub-millimeter precision, while three-dimensional coordinate measuring machines (CMM) digitize the entire axle setup and calculate exact centers automatically. These devices eliminate many human errors that creep into fieldwork and provide auditable results that fleet managers and inspectors can rely on. Yet even with access to such tools, the foundational principle holds: start with a well-documented reference point, then confirm with a secondary method to ensure consistency across measurements and conditions. In practice, this means documenting the method you used, the exact centers you identified, and any deviations observed during measurement so that the process remains transparent and repeatable.

With the centers established, the wheelbase measurement itself must be conducted along the vehicle’s longitudinal axis. The distance should be measured parallel to the truck’s length, from the center of the front axle to the center of the rear axle, with the measuring line kept straight and perpendicular to the axle centerlines. The simplest and most traditional tool for this job is a steel tape measure long enough to span the entire distance. When using a tape, fix one end at the exact front-center point and pull taut to the rear-center point, ensuring the tape remains level and in line with the axis. Any deviation from parallelism or a tilt in the tape introduces a systematic error that grows with the wheelbase length. If a laser distance meter is employed, aim the emitter precisely at the front axle center and project toward the rear axle center, maintaining a straight beam path that remains parallel to the ground and free from obstructions or reflections that could skew the readout.

Accuracy is not a one-shot affair but a disciplined practice. To minimize human error, perform the measurement at least three times from slightly different positions or angles, then compute the average. This redundancy helps smooth out small misalignments or rider-induced variations, such as tire deformation or suspension bounce. In most professional settings, technicians will corroborate the result with a cross-check, using a different instrument or a second operator to confirm the line and targets. The goal is a value that withstands scrutiny and aligns with the vehicle’s documented wheelbase in the event the data are used for regulatory compliance, load planning, or fleet analyses. When an official specification exists, use it as the final arbiter and treat any discrepancy as a prompt to re-check the reference centers and the alignment line.

The practice of wheelbase measurement extends beyond the numbers. It is a maintenance discipline that supports safer, more predictable vehicle performance. A precise wheelbase informs turning radius estimates, trailer coupling planning, and weight distribution analysis. It also matters in the context of compliance, where exact geometry can influence load limits and highway regulations. To keep measurements consistent over time, record every variable that could affect the result: surface flatness, slope, tire size, inflation pressure, and whether the vehicle is loaded or empty. Mark the axle centers permanently for your current reference if permissible, and photograph the setup to accompany the measurements. In fleets where consistency matters across many vehicles, standardize the procedure so each technician follows the same steps and uses the same type of reference points. A well-documented process reduces the risk of discrepancies that could ripple through maintenance planning or regulatory reporting.

For readers seeking practical guidance and additional perspectives on field measurements and fleet maintenance, the McGrath Trucks Blog provides broader insights that complement these hands-on methods. McGrath Trucks Blog

Measuring Wheelbase with Precision: A Practicable Guide for Commercial Trucks

The wheelbase is a fundamental dimension that quietly governs how a heavy vehicle behaves on the road. It shapes stability, steering response, weight distribution, and even how a truck negotiates a tight loading dock or a narrow bridge crossing. In a fleet maintenance program, the wheelbase is more than a static figure; it is a diagnostic reference point. When the distance between the centers of the front and rear axles deviates from specification, the signs can show up as uneven tire wear, altered ride height, or subtle handling quirks that nobody wants to chase during a busy service shift. Accuracy here is not merely a matter of curiosity. It underpins safety, compliance, and the reliability of every mission the vehicle undertakes. The wheelbase, defined as the distance between the center points of the front and rear axles measured parallel to the truck’s longitudinal axis, anchors a system of measurements and checks that keep fleets aligned with both manufacturer design and road regulations. To measure it with confidence, one must treat the task as a careful alignment exercise, not a casual guesstimate. A truck sits in its undistorted form when it is unloaded, on a level surface, with tires inflated to manufacturer specifications. Only then can the wheelbase reflect the vehicle’s true geometry rather than the compressed bounce of a loaded frame or the subtle sag of soft tires. The stance of the vehicle matters, because even small changes in ride height or axle alignment can tilt the plane of measurement. The principle is simple, but the execution requires discipline and the right tools. A clean, straight line from front axle center to rear axle center matters as much as the final number that appears on a tape. The temptation to rush through the process is strong in busy shops, yet the correct approach rewards accuracy with long-term benefit: better inspection data, more reliable maintenance planning, and fewer false alarms during periodic safety checks. To commit to accuracy, begin with preparation that is not glamorous but essential. Park the truck on a flat, level concrete floor, free of slope or crown. Remove any cargo, trailers, or attachments that could pull the vehicle out of its neutral stance. Ensure the tires are at the recommended pressure; underinflated tires can flatten and distort axle geometry, while overinflation can produce a slightly higher stance that skews measurements. Stand the truck squarely, with the front wheels pointing straight ahead and the vehicle centered in the measurement zone. The goal is to let the chassis adopt its true geometry, without the influence of loaded weight, tire deformation, or wheel misalignment. Once the vehicle’s baseline is established, identifying the precise measurement points becomes the next crucial step. For the front axle, the center is typically the midpoint of the front axle housing or the hub assembly between the two wheels. For the rear axle, it is the midpoint of the rear axle housing or, in a tandem-axle configuration, the center of the first rear axle. In practice, the first rear axle center is the critical reference when multiple rear axles exist, because it represents the effective wheelbase that determines payload placement and drivetrain efficiency. With geometry defined, the choice of tools becomes the practical hinge on which accuracy rests. A rigid steel tape measure is the traditional workhorse. It must be long enough to bridge the distance without bending or sagging, and it should be used with a straight edge to maintain a taut, straight line. In larger vehicles, a laser distance meter not only provides easy reach but also reduces human error by delivering a direct line-of-sight measurement from front axle center to rear axle center. Professional measurement setups sometimes employ dedicated wheelbase gauges. These are purpose-built rulers or jigs designed to straddle the axles and lock onto the center points, maintaining parallelism and minimizing the chance of misalignment during the measurement. If a tape measure is used, a rigid straight edge—such as a steel ruler or leveling bar—helps keep the tape taut and the measurement line true. The essence of accuracy lies in correct point identification. The front axle center is generally the midpoint of the axle housing, while the rear axle center is the midpoint of the differential housing. Marking these reference points in advance can save time and prevent drift during the measurement process. It is crucial to avoid using tire tread or sidewall as a reference, because tire wear, inflation variations, and contact patch dynamics can misrepresent the true axle center. The measurement itself should be performed with the line parallel to the ground and perfectly perpendicular to the axle centers. Any angular deviation translates into a geometric error that grows with distance, producing a result that bears little resemblance to the actual wheelbase specified by the manufacturer. To minimize error, perform at least three measurements from different positions and calculate an average. This practice accounts for small inconsistencies in stance, sensor alignment, or human error. In a professional setting, a certified technician using alignment equipment can provide an extra layer of assurance, especially when the wheelbase figure feeds critical safety assessments or regulatory reporting. After collecting data, compare your measured wheelbase with the manufacturer’s spec found in the service manual or the VIN-based documentation. Most fleets expect measurements to fall within a tight tolerance, often a few millimeters, depending on the vehicle’s age and condition. Deviations beyond this tolerance should prompt a closer inspection to identify root causes such as frame distortion, bent suspension components, or misaligned axles that could compromise handling and load stability. When high precision is required, or when a vehicle operates in a fleet with stringent safety standards, commissioning a measurement at a certified repair facility is a prudent move. These centers routinely house more advanced tools and cross-check methodologies, including laser-based alignment systems that can simultaneously verify wheelbase, track width, and axle positioning. The broader objective is not simply to obtain a single number, but to confirm the vehicle’s geometry is true to its design and within the parameters that ensure predictable steering, even weight distribution, and compliant operation on roadways and at inspection points. In practice, a measured wheelbase is most valuable when it informs maintenance planning and safety checks. It can highlight subtle changes over time that might signal frame stress, suspension wear, or early mounting shifts from heavy loads. This awareness aligns with broader industry standards and best practices that fleets adopt to maintain roadworthiness and to stay aligned with regulatory expectations. For those who want a broader perspective on measurement standards and operational benchmarks, the MCGrath Trucks blog offers practical, hands-on context that complements the technical method described here. MCGrath Trucks blog. In addition, industry-wide guidance emphasizes the benefit of corroborating measured values with official specifications and using professional services when discrepancies arise. The aim is not to produce a one-off number but to maintain a traceable measurement history that can support audits, tear-down assessments after impact events, and ongoing preventative maintenance plans. The wheelbase measurement is a thread that ties together design intent, on-road performance, and compliance realities. When approached with methodical preparation, correct point identification, and disciplined measurement technique, the result is a reliable metric that anchors a fleet’s approach to safety and efficiency. For readers seeking broader external validation and standards, the American Trucking Associations provide extensive resources on measurement practices and safety compliance at their official site: https://www.trucking.org/.

Reading the Wheelbase Blueprint: Why Manufacturer Specs Matter for Stability, Compliance, and Field Accuracy

The wheelbase isn’t just a number you jot down from a specification sheet; it is the truck’s fundamental skeleton, the distance that governs how the vehicle behaves on the road, how it carries weight, and how it complies with road and fleet regulations. In practical terms, the wheelbase is the distance between the center point of the front steering axle and the center point of the rear drive or tandem axle, measured along the vehicle’s longitudinal axis. This definition may sound precise, even clinical, but it anchors decisions that ripple through stability, maneuverability, tire wear, and the way a truck handles heavy loads across highways and through loading docks. To truly measure with confidence, one must align the practice with the manufacturer’s specifications while recognizing how real-world variables—weight distribution, suspension geometry, and even tire size—can tug that measurement a little off the page. The manufacturer’s wheelbase isn’t just a datum; it is a crafted standard that ensures consistency across models and across the service life of a truck, enabling yards, fleets, and regulators to speak the same language when they discuss stability, towing, or chassis compatibility with trailers and accessories. When you consider a truck’s stability profile, the wheelbase becomes a critical factor. A longer wheelbase tends to smooth ride quality and improve straight-line stability at highway speeds, especially under heavy load during highway en route. A shorter wheelbase, conversely, improves maneuverability in urban or dockside environments but can introduce more dynamic pitching under braking or acceleration if not paired with the right suspension tuning and weight distribution. In regulation-heavy contexts, the wheelbase also influences how a vehicle is classified and how axle weights and load limits are interpreted under applicable rules. These considerations aren’t theoretical. They shape how fleets plan routes, how retrofit projects are scoped, and how warranties or service agreements define alignment with original chassis geometry. This is why manufacturer specifications matter so deeply: they establish a baseline that ensures every assessment, adjustment, or replacement is anchored to the vehicle’s designed geometry rather than to an approximate reconstruction after years of use. In the broader landscape of measurement, the standard method—the front axle center to the rear axle center, measured parallel to the truck’s length—helps guarantee comparability across models and across service centers. This consistency is essential when a technician or estimator must verify a wheelbase before matching a trailer, planning a new suspension package, or evaluating compatibility with a different cab or drivetrain setup. For anyone who wants to delve deeper into the practicalities and to cross-check procedures with authoritative guidance, a comprehensive reference can be found within industry resources that outline the correct approach to semi-trucks’ wheelbase measurement. In the meantime, the goal remains clear: capture a measurement that reflects the vehicle’s true geometry, not one distorted by load, surface irregularities, or reading errors. With that objective in mind, the measurement should be performed on a level, flat surface and with the truck in a representative state. The truck should be empty or at least unloaded to reflect its standard wheelbase, bearing in mind that loading can subtly affect geometry through spring deflection, axle alignment, and tire contact patch changes. Tire inflation must mirror the manufacturer recommendations because underinflation or overinflation alters the tire’s footprint and can skew the perceived distance between axles when a tape measure is used or when a laser is pointed along an imperfect line. The front axle center is typically the midpoint of the front axle beam or the hub assembly, while the rear axle center is the midpoint of the rear axle beam or the hub of the drive axles. In trucks with multiple rear axles, the wheelbase is usually measured from the front axle center to the center of the first rear axle. This practice underpins consistency, as every measurement thereafter—whether in a fleet shop, a service facility, or a regulatory inspection—relies on the same reference points. The tools you choose should reflect the scale of the job. A steel tape measure remains the workhorse for most shop floors: it is long enough to span the distance and non-stretchable enough to preserve accuracy when pulled taut. For larger rigs, a laser distance meter offers an advantage when reaching the rear axle from the front is impractical or when a straight line path is difficult to align by eye. The precision of a laser driver is not a substitute for understanding the geometry; it complements the need to keep the measuring line parallel to the ground and perpendicular to the axle centers. The process itself should be carried out with attentiveness. Place one end at the front axle center, then extend the measurement toward the rear axle center, keeping the line straight and the measurement plane level. Any slope or angle introduced by an uneven surface or by the line not perfectly parallel to the vehicle’s length will yield a reading that’s biased by geometry rather than by the actual chassis spread. After obtaining a first reading, repeat it from at least two alternate vantage points to reduce the chance that a single misalignment or an odd angle in the tape’s placement biased the result. Averaging three or more readings is standard practice when the goal is a defensible, reference-quality value. In professional settings, technicians may use alignment-grade equipment that immobilizes the vehicle and ensures the axle centers and the measuring path are fixed in position. This level of precision is appropriate when the wheelbase must be documented for a heavy retrofit, for compliance review, or when precise matching with a trailer or a replacement chassis is required. Beyond the mechanics of measurement itself lies the broader implication: the wheelbase you verify against a manufacturer’s spec is the baseline for stability and safety. If the measured wheelbase diverges from the spec by more than a small tolerance, a fleet manager will need to audit the vehicle’s condition—suspension wear, axle misalignment, or previous modifications could be responsible. In cases where a vehicle has undergone suspension changes or has been rebuilt, the wheelbase can drift from the original specification. This drift might be intentional, as part of a body-on-frame replacement or a cab swap, or it could be the consequence of wear and tear. Either way, confirming the wheelbase against the manufacturer’s documented dimension is essential to ensure that load distribution remains within intended limits and that the vehicle’s geometry still supports safe braking, steering response, and stable highway behavior. For readers seeking a broader, practical framework, the Complete Guide to Accurately Measuring a Semi Truck provides rigorous steps and illustrations that complement this discussion. It serves as an external resource that field technicians consult to align on best practices and measurement discipline. If you want to explore related topics and stay connected with ongoing discussions about truck specifications and measurement, the broader industry blog space can be a valuable companion resource. McGrath Trucks blog can offer accessible commentary and practical perspectives that weave together measurement discipline with fleet-level considerations. For readers who want to organize their own research and keep a record of measurements, maintain a simple log that notes the vehicle’s state (empty, fuel level, tire pressure), the exact axle centers used, the tools and methods employed, and the three or more readings and their average. A well-documented approach not only supports compliance and quality control but also makes it easier to compare like-for-like vehicles when evaluating used or rebuilt trucks. In the broader landscape of commercial trucking, measurement integrity supports fleet planning, regulatory compliance, and the accuracy of aftermarket modifications. It helps ensure that a new trailer couples correctly, that axle loads align with road-use expectations, and that the vehicle’s behavior under load is predictable and within design tolerances. The wheelbase is more than a dimension; it is the geometric heartbeat of the chassis that informs how weight moves through the frame, how the suspension responds, and how the machine respects the highway. As with any specialized task, always cross-check the measured values with the manufacturer’s published dimensions and, when in doubt, consult the service manual or a certified technician. The discipline of precise measurement is a quiet form of insurance—one that keeps a fleet aligned with safety, performance, and compliance. External reference: The Complete Guide to Accurately Measuring a Semi Truck https://www.truckequipment.com/blog/complete-guide-to-accurately-measuring-a-semi-truck

Final thoughts

Accurately measuring the wheelbase of a commercial truck is not merely a procedural task but a cornerstone of effective fleet management and operational efficiency. The outlined steps—preparation, identification of axle centers, proper tools, measurement techniques, and adherence to manufacturer specifications—form a comprehensive method that ensures precision in this essential measurement. Fleet managers, trucking company owners, and procurement teams must prioritize this aspect of maintenance to optimize vehicle performance, enhance safety, and prolong the lifespan of their assets. By committing to these best practices, professionals can drive their fleet towards greater efficiency and improved service delivery.